November 12, 2024 4:40 pm

On the planet of welding, shielding gasoline is an important part for creating robust, high-quality welds. Whether or not you’re knowledgeable in welding outlets or a DIY gasoline welder, understanding the position of protecting gasoline can considerably enhance your welding outcomes. Shielding gases are used to guard the weld space from contaminants and affect the weld’s ultimate properties. This text dives deep into the significance of protecting gases, their varieties, and the way to decide on the appropriate one on your welding wants.

Why is Shielding Gasoline Vital in Welding?

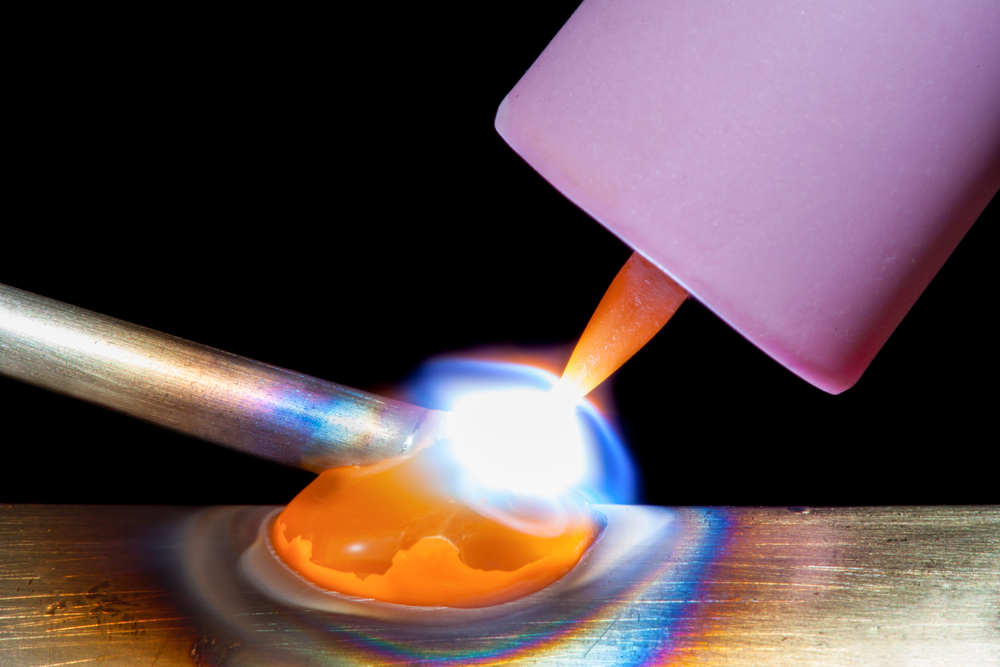

Shielding gasoline performs a basic position within the welding course of by offering a protecting barrier between the molten weld pool and the ambiance. With out shielding gasoline, atmospheric gases like oxygen, nitrogen, and hydrogen can simply react with the molten steel, resulting in weld defects equivalent to porosity, cracking, and oxidation. These points compromise the structural integrity and look of the weld, making shielding gasoline essential for high-quality, sturdy welds.

Utilizing the appropriate shielding gasoline helps management the weld’s warmth distribution, penetration, and look. It may possibly additionally impression elements like arc stability, spatter ranges, and steel switch modes, all of which straight affect the convenience and effectiveness of the welding course of in each skilled and residential welding setups.

Sorts of Shielding Gases

Choosing the suitable shielding gasoline is dependent upon the kind of steel you’re working with, the welding course of, and the specified weld traits. There are a number of generally used shielding gases in welding, every with distinctive properties that make them appropriate for particular functions.

Argon (Ar)

Argon is a extensively used shielding gasoline, significantly in gasoline steel arc welding (GMAW) and gasoline tungsten arc welding (GTAW). Its inert properties make it superb for safeguarding the weld pool with out reacting with it, and it creates a easy, secure arc. Argon is very efficient for welding non-ferrous metals like aluminum, magnesium, and copper.

Argon gives:

- Improved arc stability

- Lowered spatter

- Higher weld look

Nevertheless, for metal welding, pure argon is usually utilized in mixture with different gases to keep away from points with penetration and weld high quality.

Carbon Dioxide (CO₂)

Carbon dioxide is often utilized in gasoline welding for its affordability and effectiveness. Pure CO₂ is usually utilized in gasoline steel arc welding (GMAW) for carbon metal. Nevertheless, it tends to provide extra spatter in comparison with different shielding gases.

Benefits of CO₂ embody:

- Deeper weld penetration

- Value-effectiveness

- Perfect for thicker supplies

Nevertheless, its reactive nature may cause oxidation within the weld, and it isn’t appropriate for non-ferrous metals. CO₂ is usually combined with argon in gasoline welding to steadiness penetration and scale back spatter.

Argon-CO₂ Combine

A mix of argon and CO₂ is usually utilized in welding outlets to supply the advantages of each gases. A typical combination is 75% argon and 25% CO₂, which mixes the sleek arc of argon with the deeper penetration of CO₂, leading to a cleaner weld with fewer spatter points. This mix is standard for welding gentle metal and provides a superb steadiness between weld high quality and cost-effectiveness.

Helium (He)

Helium is one other inert gasoline usually used as a shielding gasoline, particularly for supplies like stainless-steel, aluminum, and copper. Helium is dearer than different gases however gives hotter arcs, which permits for quicker welding speeds and deeper penetration. Helium is usually combined with argon in varied ratios, relying on the specified weld traits.

Helium is good for:

- Thick supplies

- Excessive warmth conductivity metals

- Quicker welding speeds

As a result of helium is much less dense than argon, increased circulate charges are required to realize efficient shielding, which may make it extra expensive for intensive initiatives.

Oxygen (O₂) and Nitrogen (N₂)

Oxygen and nitrogen are typically added in small percentages (normally 1–5%) to different gases to enhance weld traits. For instance, including a small quantity of oxygen to argon can improve arc stability and enhance penetration, particularly in metal welding. Nitrogen, alternatively, is extra specialised, usually used for stainless-steel and different alloys to enhance corrosion resistance.

Find out how to Select the Proper Shielding Gasoline

Selecting the proper shielding gasoline is crucial for attaining optimum weld high quality, and it is dependent upon a number of elements, together with the welding course of, the kind of steel, and the specified traits of the weld.

Welding Course of

Every welding course of has particular necessities for shielding gases. For instance, MIG welding usually makes use of a mixture of argon and CO₂, whereas TIG welding sometimes makes use of pure argon. Stick welding, alternatively, typically doesn’t require shielding gasoline because the electrode coating gives safety.

Understanding which gasoline pairs finest with every welding technique can save each money and time within the welding store and enhance the standard of the completed product.

Materials Kind

Completely different supplies require particular shielding gases for optimum outcomes:

- Metal: For carbon metal, a mixture of argon and CO₂ is usually used to steadiness price and efficiency. Chrome steel welding would possibly require a combination of argon with CO₂ or perhaps a small quantity of oxygen.

- Aluminum and Magnesium: Pure argon or a mixture of argon with helium works finest for these non-ferrous metals to keep away from contamination and obtain a easy weld.

- Copper and Bronze: Helium or a helium-argon combine gives the excessive warmth wanted for welding these metals successfully.

Weld Look and Penetration Necessities

Some welding jobs require deep penetration, whereas others prioritize a clear, visually interesting weld. Helium is useful for deeper penetration, whereas argon gives smoother, extra aesthetic welds. The ratio of CO₂ in an argon combine also can have an effect on penetration and spatter ranges, permitting welders to fine-tune the gasoline choice based mostly on particular job necessities.

Shielding Gasoline Security and Dealing with Suggestions

Dealing with and storing shielding gases requires consideration to security, particularly in welding outlets the place gasoline cylinders are widespread. Listed here are some key security ideas:

- Correct Storage: Retailer gasoline cylinders upright and safe them to forestall falling. Keep away from direct daylight and excessive temperatures.

- Cylinder Dealing with: Use a cylinder cart to move gasoline cylinders and all the time put on protecting gloves when dealing with them.

- Regulator Upkeep: Often examine gasoline regulators and connections for leaks. A small leak can result in wasted gasoline, and within the case of flammable gases, it may pose a security hazard.

- Air flow: Guarantee satisfactory air flow within the welding space to forestall gasoline buildup, which may be hazardous to well being and security.

Following these tips may also help defend each welders and the work atmosphere.

The Position of Shielding Gasoline in Completely different Welding Environments

The selection of protecting gasoline varies considerably between skilled welding outlets and particular person gasoline welder setups. In a welding store, it’s widespread to search out a wide range of gasoline mixes readily available, as completely different initiatives might name for various gases to realize the perfect outcomes. Skilled welders in these outlets can alter the gasoline combine to satisfy particular undertaking necessities.

For DIY or residence welding, price and ease usually affect gasoline choice. Many residence gasoline welders desire a CO₂-argon combine, which is flexible and works nicely on a spread of gentle metal functions. Whereas pure CO₂ is probably the most inexpensive choice, welders might go for combined gases to realize cleaner, much less porous welds.

The Important Position of Shielding Gasoline in Welding

Shielding gasoline is a cornerstone of high quality welding, providing each safety and management over the welding course of. From enhancing arc stability to stopping oxidation, shielding gasoline impacts each side of weld high quality and sturdiness. In welding outlets and particular person gasoline welding setups, selecting the best shielding gasoline could make the distinction between a robust, easy weld and one riddled with defects.

Whether or not you’re a skilled welder or a hobbyist, understanding the properties of protecting gases may also help you produce cleaner, stronger welds tailor-made to your particular wants. The funding in correct shielding gasoline pays off in improved weld high quality, fewer repairs, and a extra environment friendly welding course of total.

Want Metal Fabricators in Hermiston, OR?

NW Metallic Fabricators, Inc. is a family-owned enterprise that has been servicing prospects in Hermiston, Oregon since 1986. We now have greater than 100 years of expertise within the food-processing business and specialize within the customized manufacturing of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metallic Fabricators, Inc. is an accredited member of the native Chamber of Commerce. We’re a devoted enterprise the place high quality all the time comes first. Our prospects know that they will rely on us to ensure that their merchandise are hand-crafted to satisfy their specs. Contact us at the moment to study extra about what we will do for you!

Categorised in: Welding

This submit was written by admin