Even in in the present day’s difficult manufacturing setting, Miller Fabrication Options meets Unique Gear Producer (OEM) demand for complicated, prefabricated metallic components, comparable to engine crankcases and enormous saddle mount plates. Counting on a confirmed, end-to-end weldment course of coupled with a dedication to steady weldment enchancment, Miller manages provide chain and labor challenges and incorporates value-added options that concurrently decrease prices and enhance high quality.

Recapping the preliminary levels of fabrication mission administration

In October, Miller gave clients, prospects and college students insights into these vertical integration capabilities throughout “The Life Cycle of a Weldment,” a two-part webinar collection created for Manufacturing Day 2021. Half One of many webinar collection demonstrated the first three levels of Miller’s mission administration course of: session/quoting, mission growth and materials processing.

- Within the session/quoting part, Miller determines mission match, discussing blueprint specs with the OEM and making suggestions for any modifications which will scale back manufacturing prices with out sacrificing product high quality.

- An inside group of engineering, course of growth, customer support, planning and high quality specialists onboard new tasks in the course of the mission growth part. Throughout this second step within the mission administration course of, Miller customizes a manufacturing plan and employs half approval protocols to make sure high quality weldments all through the life cycle of the mission.

- Within the third, or materials processing stage, Miller acquires supplies effectively and affordably, reworking them into quality-checked components that meet each buyer requirement. Engineers and highly-skilled trades individuals use robotics, state-of-the-art machines and confirmed strategies to chop, grind, weld, machine, blast and paint merchandise to actual specs, as verified by Miller high quality specialists. Every operation undergoes a standardized inspection to evaluate important checks earlier than a component proceeds to the subsequent stage.

Readying heavy tools components for utility

In Half 2 of “The Life Cycle of a Weldment” webinar collection, Miller highlighted the ultimate two levels of its mission administration course of, the place components are readied to start their working life.

Stage 4 – Element Completion

Because the title implies, Miller completes tasks and handles the kitting course of, the place separate-but-related objects are grouped, packaged and provided collectively as a single unit. The kitting store order, which lists the components to assemble in a equipment, is likened to a cake recipe. The “putaways,” or accomplished elements, then are delivered on to the point-of-use within the manufacturing course of. They could be despatched to the fabrication store, which “bakes the cake,” after which the machine store for “frosting.”

Lastly, Miller packages accomplished elements and readies them for cargo to the OEM’s vacation spot location(s), oftentimes a producing plant for ending touches and full meeting or on to an OEM’s buyer facility.

Stage 5 – Mission Assessment

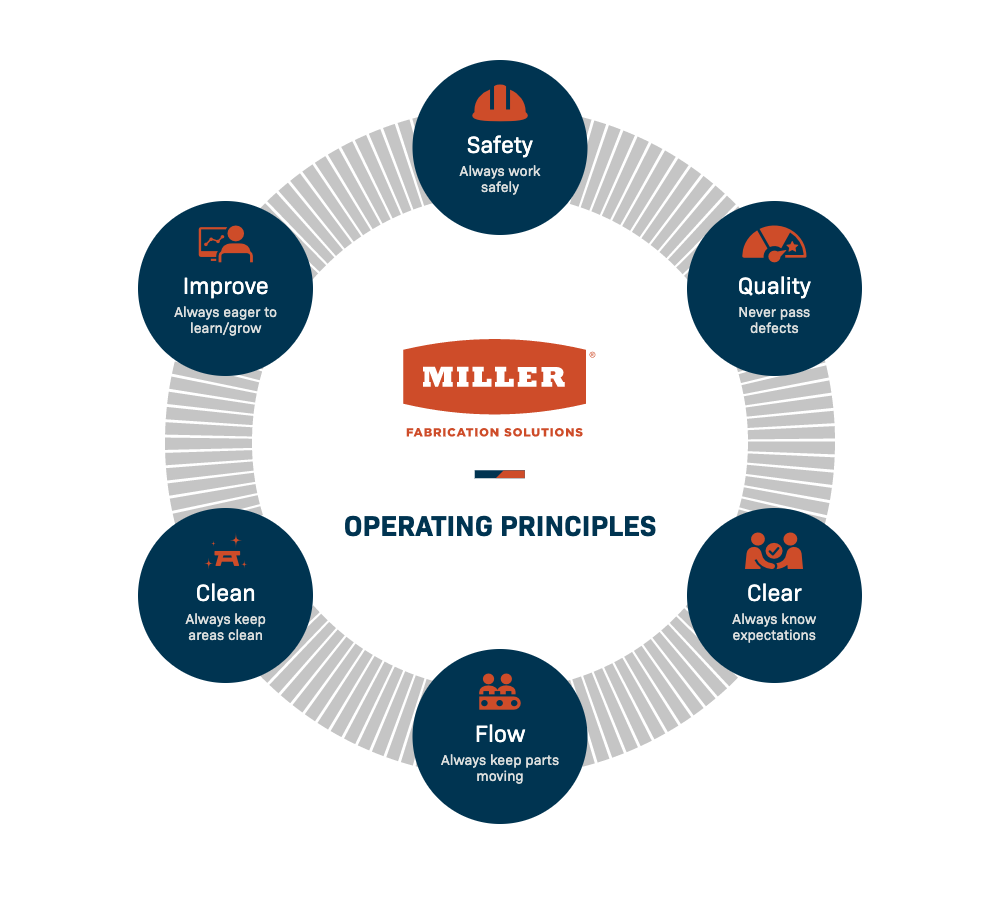

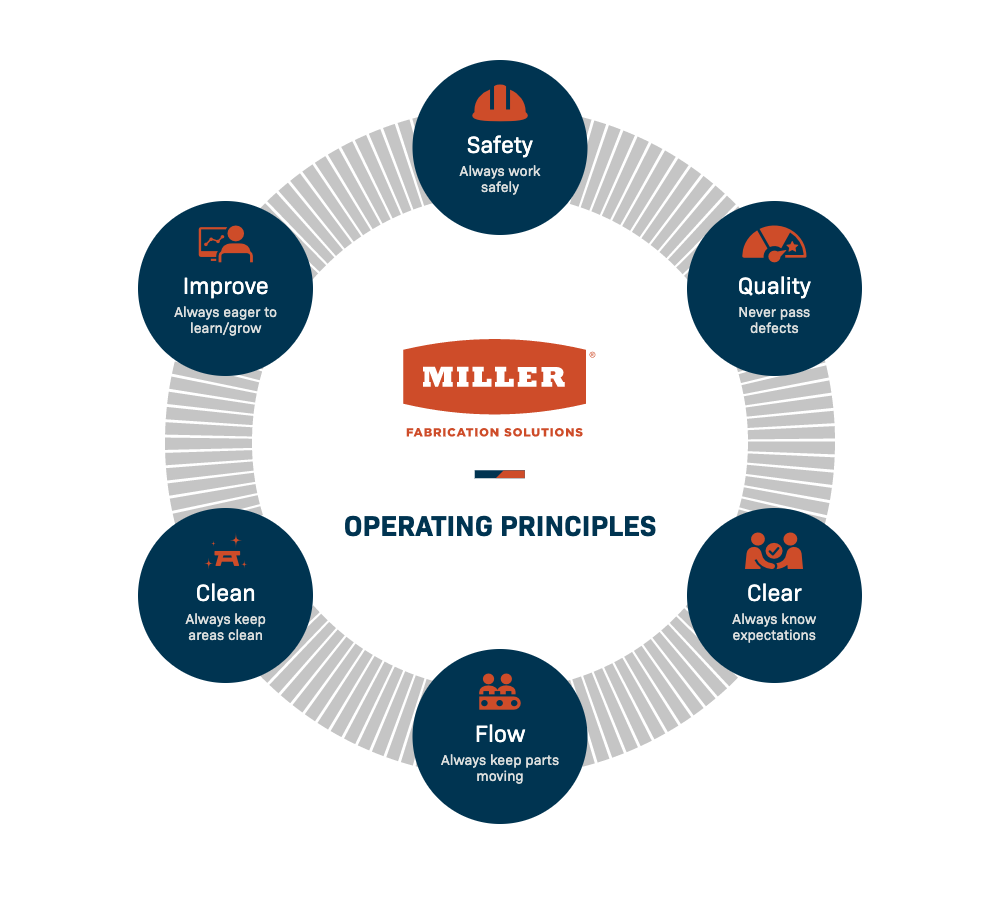

After components have shipped, a Miller group revisits buyer tasks to establish alternatives for course of enhancements. This technique aligns with one of many fabricator’s six working ideas – “Enhance.”

By participating in steady enchancment, Miller produces higher components sooner. Steady enchancment may be within the type of analysis of recent tools and strategies, together with robotics and automation, and making use of them to current processes the place applicable to cut back manufacturing setup and cycle time, improve high quality and improve velocity and accuracy.

Miller is on the forefront of creating modern processes to provide high quality metallic components that persistently meet exacting requirements and preserve OEM tools manufacturing traces transferring. Learn extra about Miller’s steady weldment enchancment efforts right here and contact Miller to find out how your weldment mission may be strategically managed for repeatable success.