January 27, 2025 3:16 pm

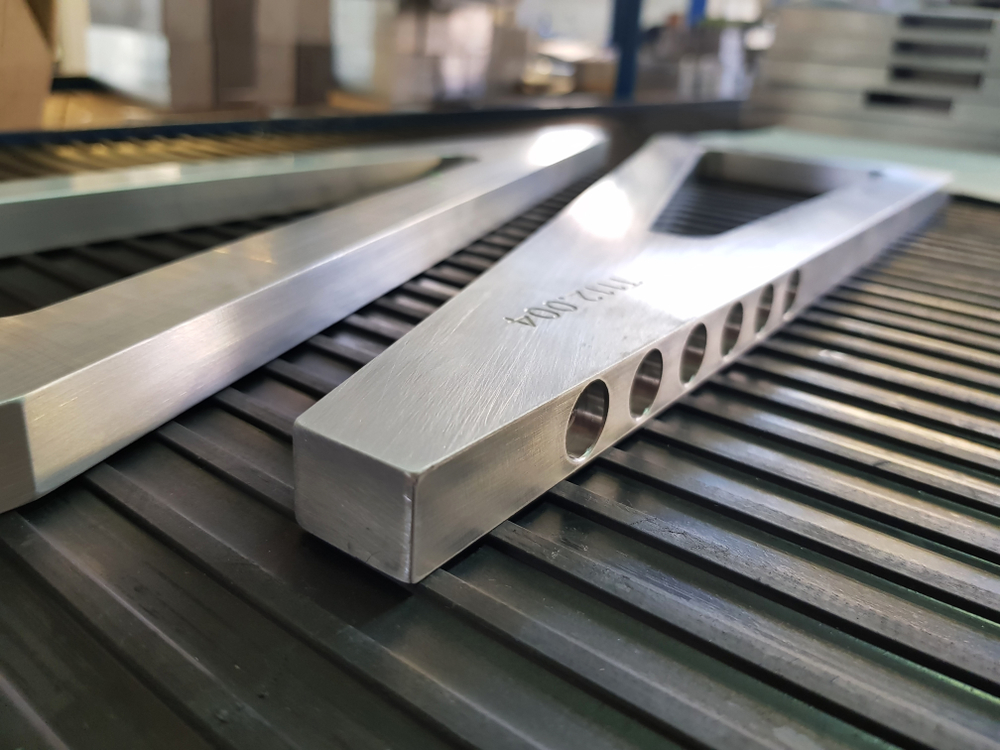

Metallic fabrication permits the creation of every thing from industrial equipment to bespoke architectural parts. Whether or not crafting large-scale elements or intricate customized designs, precision in steel fabrication is paramount. It ensures not solely aesthetic attraction but additionally performance, sturdiness, and security. On this weblog, we discover the significance of precision in customized steel fabrication and the strategies employed to ensure high-quality outcomes.

Understanding Customized Metallic Fabrication

Customized steel fabrication includes reworking uncooked steel into particular constructions or merchandise tailor-made to distinctive necessities. This course of spans a number of phases, together with chopping, shaping, assembling, and ending. Every stage calls for accuracy and a focus to element to make sure that the ultimate product meets the specified specs.

Key Components of the Fabrication Course of

- Design and Planning: Each customized steel fabrication mission begins with detailed design and planning. Pc-Aided Design (CAD) software program is commonly used to create exact blueprints and fashions that information the manufacturing course of.

- Materials Choice: Selecting the best steel is vital. Elements equivalent to power, corrosion resistance, and weight are thought of to match the fabric to the mission’s necessities.

- Slicing and Shaping: Strategies like laser chopping, water jet chopping, and CNC machining are employed to form steel elements with excessive precision.

- Meeting and Welding: Parts are joined collectively utilizing superior welding strategies, guaranteeing sturdy and sturdy bonds.

- Ending: Processes equivalent to sharpening, coating, and portray improve the product’s aesthetic and protecting qualities.

Every step is interconnected, that means that errors at any stage can compromise the standard and performance of the completed product. This is the reason precision is indispensable.

Why Precision Issues in Metallic Fabrication

The position of precision extends past aesthetics; it impacts the structural integrity, performance, and longevity of the product. Listed here are the important thing the reason why precision is significant:

Making certain Structural Sturdiness

Sturdiness in steel fabrication is intently linked to the accuracy of the method. Poorly reduce or misaligned elements can create weaknesses, compromising the structural integrity of the product. Precision ensures that each half suits completely and features as meant, leading to a strong and long-lasting construction.

Enhancing Performance

In purposes equivalent to equipment, instruments, or complicated assemblies, even minor inaccuracies can result in malfunctions. For instance, improperly aligned elements may cause friction, put on, or full failure. By sustaining precision, customized steel fabrication delivers merchandise that carry out seamlessly underneath numerous circumstances.

Aesthetic Enchantment

Precision is equally vital in tasks the place look issues, equivalent to architectural installations or ornamental parts. Clear traces, clean finishes, and exact detailing contribute to the visible affect of the product, enhancing its total worth.

Price-Effectiveness

Whereas precision could require superior instruments and meticulous consideration to element, it reduces pricey errors and rework. Correct fabrication minimizes materials waste and ensures that the product is constructed proper the primary time, saving each money and time.

Security Compliance

Many fabricated steel merchandise are utilized in vital purposes, equivalent to building or transportation. Precision ensures compliance with security requirements, decreasing the danger of accidents and guaranteeing the well-being of customers.

Instruments and Strategies That Guarantee Precision

Attaining precision in customized steel fabrication depends on superior instruments, strategies, and expert craftsmanship. Beneath are a few of the key strategies employed to make sure high quality:

Superior Equipment

Fashionable fabrication amenities are geared up with state-of-the-art equipment designed for accuracy and effectivity.

- Laser Slicing Machines: Present exact cuts with minimal materials waste.

- CNC Machines: Allow automated, extremely correct chopping, drilling, and milling operations.

- Robotic Welding Methods: Guarantee constant and high-quality welds, decreasing human error.

Measurement and High quality Management Instruments

To confirm precision, measurement instruments equivalent to calipers, micrometers, and coordinate measuring machines (CMM) are used all through the fabrication course of. These instruments enable for real-time changes, guaranteeing that elements meet precise specs.

Expert Workforce

Even with superior equipment, the experience of expert fabricators performs a vital position. These professionals perceive the properties of various metals, interpret complicated designs, and execute processes with meticulous consideration to element.

High quality Assurance Protocols

Complete high quality assurance processes are important to uphold precision. Common inspections, materials testing, and adherence to trade requirements be sure that the completed product meets all necessities.

Challenges in Attaining Precision

Regardless of developments in expertise, precision steel fabrication isn’t with out its challenges. Addressing these points requires proactive measures and steady enchancment.

Materials Variability

Metals can range in high quality and composition, affecting their habits throughout fabrication. Rigorous materials choice and testing assist mitigate this variability.

Advanced Designs

As customized designs change into extra intricate, guaranteeing precision turns into tougher. Superior CAD software program and simulation instruments help in planning and executing complicated tasks.

Tools Calibration

Precision equipment requires common upkeep and calibration to carry out optimally. Neglecting this side can lead to inaccuracies and delays.

Expert Labor Scarcity

The demand for expert steel fabricators usually exceeds provide, posing a problem for a lot of producers. Investing in coaching packages and apprenticeship alternatives is essential to constructing a succesful workforce.

Improvements Driving Precision in Metallic Fabrication

The sphere of steel fabrication is repeatedly evolving, with improvements geared toward enhancing precision and effectivity. Among the newest developments embody:

Synthetic Intelligence (AI) and Machine Studying

AI-powered techniques analyze knowledge from fabrication processes to determine patterns and optimize operations. Machine studying algorithms can predict potential points, permitting for preemptive changes.

Additive Manufacturing

Often known as 3D printing, additive manufacturing permits the creation of complicated steel constructions with unparalleled accuracy. This expertise is very helpful for prototyping and producing intricate elements.

Web of Issues (IoT) Integration

IoT-enabled units present real-time monitoring of fabrication processes, guaranteeing precision at each stage. Sensors and linked techniques improve effectivity and cut back the chance of errors.

Superior Welding Applied sciences

Strategies equivalent to laser welding and friction stir welding supply superior precision and power, increasing the probabilities for customized steel fabrication.

Case Research: Precision in Motion

Aerospace Parts

Within the aerospace trade, precision is non-negotiable. Fabricated steel elements should face up to excessive circumstances and meet rigorous security requirements. Strategies like CNC machining and robotic welding be sure that these elements are manufactured to precise specs.

Architectural Installations

For tasks like trendy skyscrapers or intricate sculptures, precision fabrication ensures that every aspect suits seamlessly. Superior chopping and ending strategies contribute to the visible and structural integrity of those installations.

Medical Tools

Metallic fabrication is vital in producing medical units and gear, the place precision straight impacts performance and affected person security. Strategies like laser chopping and additive manufacturing are generally used to create intricate elements.

How We Prioritize High quality in Customized Metallic Fabrication

At our facility, we’re dedicated to delivering the very best requirements of precision and high quality in each mission. Right here’s how we obtain this:

Rigorous Planning and Design

Each mission begins with detailed planning and design. Our workforce works intently with purchasers to know their wants and create correct blueprints utilizing superior CAD software program.

Funding in Expertise

We leverage cutting-edge equipment and instruments to make sure precision at each stage of the fabrication course of. From laser chopping to robotic welding, our gear is frequently maintained and calibrated for optimum efficiency.

Expert Craftsmanship

Our workforce of skilled fabricators brings a wealth of data and experience to each mission. Their consideration to element ensures that every product meets or exceeds shopper expectations.

Complete High quality Management

We implement stringent high quality management measures, together with materials testing, dimensional checks, and closing inspections. These protocols be sure that the completed product is each exact and sturdy.

Buyer-Centric Strategy

Understanding that each mission is exclusive, we prioritize open communication and collaboration with our purchasers. This strategy permits us to ship customized steel fabrication options that align completely with their necessities.

Conclusion

Precision in steel fabrication is greater than a technical requirement; it’s the basis of high quality, sturdiness, and performance. From superior instruments and expert craftsmanship to rigorous high quality management, each side of the method contributes to attaining distinctive outcomes. As customized steel fabrication continues to evolve, the emphasis on precision will stay central to assembly the ever-changing calls for of contemporary industries. By prioritizing accuracy and investing in innovation, we be sure that our purchasers obtain merchandise that stand the take a look at of time.

Want Metal Fabricators in Hermiston, OR?

NW Metallic Fabricators, Inc. is a family-owned enterprise that has been servicing prospects in Hermiston, Oregon since 1986. We now have greater than 100 years of expertise within the food-processing trade and specialize within the customized manufacturing of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metallic Fabricators, Inc. is an accredited member of the native Chamber of Commerce. We’re a devoted enterprise the place high quality at all times comes first. Our prospects know that they will rely on us to be sure that their merchandise are hand-crafted to satisfy their specs. Contact us at present to be taught extra about what we are able to do for you!

Categorised in: Metallic Fabrication

This submit was written by admin