Could 10, 2025 1:21 pm

On the subject of manufacturing, two widespread phrases that always come up are “machining” and “fabrication.” Whereas each are important processes in shaping uncooked supplies into usable merchandise, they signify distinct methods with totally different strategies and purposes. Understanding the distinction between machining and fabrication is essential for anybody concerned within the manufacturing course of, whether or not you’re a producer, engineer, or perhaps a hobbyist engaged on a mission. On this weblog submit, we are going to discover the nuances of machining and fabrication, highlighting their variations, benefits, and the way they’re utilized in varied industries.

Defining Machining

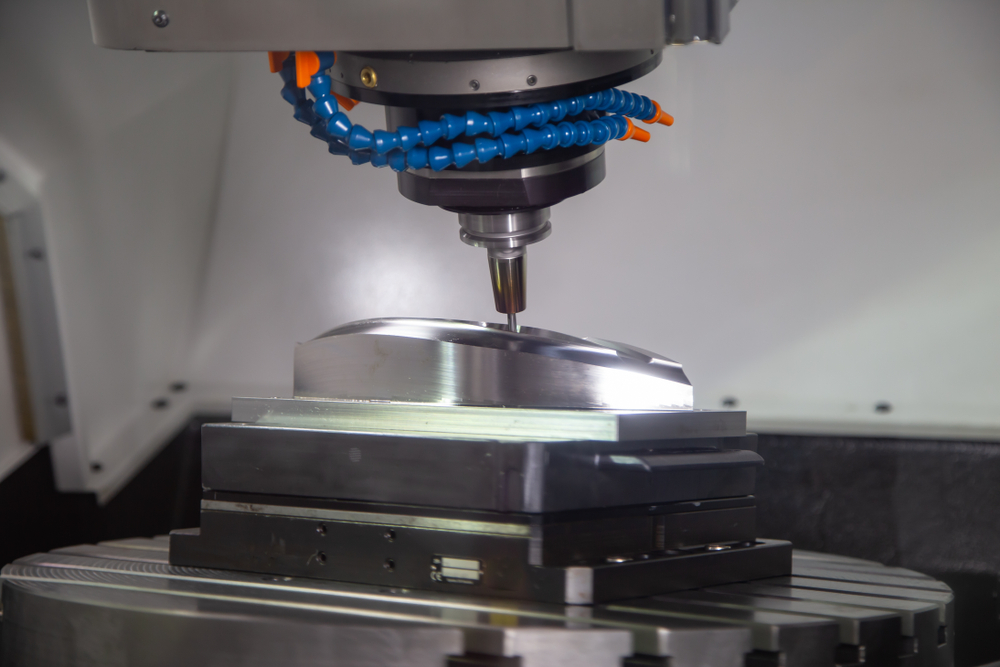

Machining is a producing course of that includes the elimination of fabric from a workpiece to attain a desired form or end. This course of sometimes makes use of instruments like lathes, mills, drills, or grinders to form and refine the fabric. The first purpose of machining is to provide exact, extremely detailed elements, typically with tight tolerances and clean surfaces. Machining is mostly used with metals, nevertheless it will also be utilized to different supplies similar to plastics and composites.

One of many key options of machining is that it begins with a stable block of fabric, and the machine instruments take away parts of that materials till the ultimate form is achieved. For example, in turning operations, a rotating workpiece is lower by a stationary device, eradicating materials layer by layer till the specified diameter or profile is reached. Equally, milling includes a rotating reducing device that removes materials from the workpiece because it strikes in a number of instructions, permitting for advanced shapes to be shaped.

Machining is an important course of in industries the place precision and accuracy are paramount, similar to aerospace, automotive, and medical gadget manufacturing. Elements like engine parts, gears, and complicated instruments typically bear machining as a result of want for prime tolerances and high quality particulars.

Understanding Fabrication

Fabrication, alternatively, is a broader time period that encompasses quite a lot of processes used to create steel buildings and merchandise. Not like machining, which includes eradicating materials from a stable block, fabrication sometimes includes increase or assembling parts. The processes concerned in fabrication embody reducing, bending, welding, assembling, and generally ending. Fabrication typically offers with bigger buildings or gadgets that require meeting from particular person elements.

For instance, in steel fabrication, a big sheet of metal may be lower into varied sizes and styles, then welded collectively to type a body for a constructing, equipment, or different infrastructure. This course of may also contain bending steel items into particular shapes or assembling pre-fabricated elements utilizing fasteners or welding. Fabrication is essential in industries like development, shipbuilding, and infrastructure growth, the place large-scale parts and buildings should be created.

The distinction in strategy between machining and fabrication is critical. Fabrication is extra about remodeling uncooked supplies right into a completed product by becoming a member of, reducing, or shaping them, typically with out the acute precision required in machining. Fabricators may use instruments like plasma cutters, lasers, or press brakes to carry out their duties, and the ensuing product could not require the high quality ending and tolerances that machining affords.

The Key Variations Between Machining and Fabrication

Whereas each machining and fabrication are important to manufacturing, the processes differ considerably by way of their strategy, gear used, and purposes. Some of the essential distinctions lies within the technique of fabric manipulation. Machining includes eradicating materials from a stable block to create the specified half, whereas fabrication sometimes builds up a construction by assembling pre-cut or pre-formed parts.

One other key distinction is the extent of precision. Machining processes, as a result of nature of their instruments and methods, can obtain a lot increased precision than fabrication processes. Machining is right for producing elements that require high quality particulars, tight tolerances, and clean finishes, similar to precision parts for equipment or medical units. Fabrication, whereas it will also be extremely correct, typically focuses extra on creating bigger buildings, similar to frames, enclosures, and even whole buildings, the place the tolerance for small imperfections is increased.

The forms of supplies utilized in every course of additionally differ. Machining is mostly used with laborious metals, similar to metal, aluminum, or titanium, however will also be utilized to softer supplies like plastics. Fabrication, alternatively, can contain a broader vary of supplies, together with metals, plastics, and even wooden, relying on the applying. In fabrication, supplies are sometimes extra versatile and might be manipulated in varied methods, similar to welding them collectively, bending them, or assembling them into bigger buildings.

Lastly, the general value and time necessities can differ between the 2 strategies. Machining is usually a extra time-consuming and costly course of due to the excessive degree of precision and the specialised gear required. In distinction, fabrication processes might be sooner and cheaper, particularly when coping with bigger volumes of elements or less complicated buildings. Nevertheless, the complexity of the design and the supplies used can even affect the price and time required for fabrication.

Functions of Machining

Machining is primarily used for producing elements that require excessive precision and high quality particulars. Among the most typical purposes of machining might be present in industries similar to aerospace, automotive, and medical gadget manufacturing. For example, within the aerospace business, machining is essential for creating parts like turbine blades, which should be fabricated to extraordinarily tight tolerances to make sure they perform accurately in high-performance environments.

In automotive manufacturing, machining is usually used to create engine parts, gears, and different essential elements that should function easily and effectively. Equally, medical units, similar to surgical devices or implants, require machining to make sure they meet strict regulatory requirements and carry out with the mandatory accuracy.

One other software of machining is within the manufacturing of advanced tooling or molds used for different manufacturing processes. For instance, machining may be used to create molds for injection molding or die-casting, the place the mould should have extremely detailed surfaces to provide high-quality elements.

Machining can also be indispensable in industries the place customized or one-off elements are required. For instance, a producer producing low volumes of a selected half could depend on machining to create exact prototypes or limited-edition merchandise.

When Fabrication is the Most popular Selection

Whereas machining is significant for a lot of industries, there are many purposes the place fabrication is the higher alternative. Fabrication is especially well-suited for creating massive, advanced buildings or assemblies the place excessive precision just isn’t the first concern. Industries similar to development, shipbuilding, and infrastructure growth rely closely on fabrication processes to construct the whole lot from bridges to massive equipment and heavy-duty gear.

Fabrication additionally performs an important function within the creation of merchandise with massive floor areas or people who should be assembled from a number of parts. For instance, within the development of buildings or bridges, steel fabrication is used to create beams, frames, and different structural components that may later be welded, bolted, or mounted collectively. Equally, within the automotive business, fabrication is usually used to create massive physique panels or structural parts earlier than they’re welded or bolted into place on the car’s body.

Moreover, fabrication is the go-to course of for creating prototypes or small batches of merchandise that don’t require the precision that machining affords. Since fabrication can contain processes like welding and reducing, it could actually typically be sooner and cheaper when working with massive elements or assemblies.

Conclusion

Machining and fabrication are each important processes within the manufacturing world, every serving totally different wants and purposes. Machining focuses on eradicating materials from a stable block to create exact, detailed elements with tight tolerances, making it best for industries that require excessive accuracy and clean finishes. Fabrication, alternatively, includes the meeting of elements and the shaping of supplies to type bigger buildings, making it the popular technique for constructing large-scale merchandise and assemblies.

Understanding the distinction between machining and fabrication may help producers, engineers, and even hobbyists make the fitting alternative for his or her tasks. Whether or not precision is the precedence or large-scale meeting is required, each machining and fabrication provide distinctive benefits that cater to particular manufacturing wants.

Want Metal Fabricators in Hermiston, OR?

NW Steel Fabricators, Inc. is a family-owned enterprise that has been servicing clients in Hermiston, Oregon since 1986. We’ve greater than 100 years of expertise within the food-processing business and specialize within the customized manufacturing of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Steel Fabricators, Inc. is an accredited member of the native Chamber of Commerce. We’re a devoted enterprise the place high quality at all times comes first. Our clients know that they’ll depend on us to be sure that their merchandise are hand-crafted to satisfy their specs. Contact us in the present day to study extra about what we will do for you!

Categorised in: Machining, Steel Fabrication

This submit was written by admin