March 7, 2025 6:25 pm

Shearing is a basic course of in machining that performs an important position in slicing, shaping, and forming supplies. It is among the most generally used strategies in industries that cope with metalworking, automotive manufacturing, aerospace manufacturing, and varied different sectors. By understanding the shearing course of in machining, engineers and producers can optimize their manufacturing processes to realize excessive effectivity and precision. This weblog delves into the mechanics of shearing, its functions, benefits, and kinds of shearing machines.

Understanding the Shearing Course of in Machining

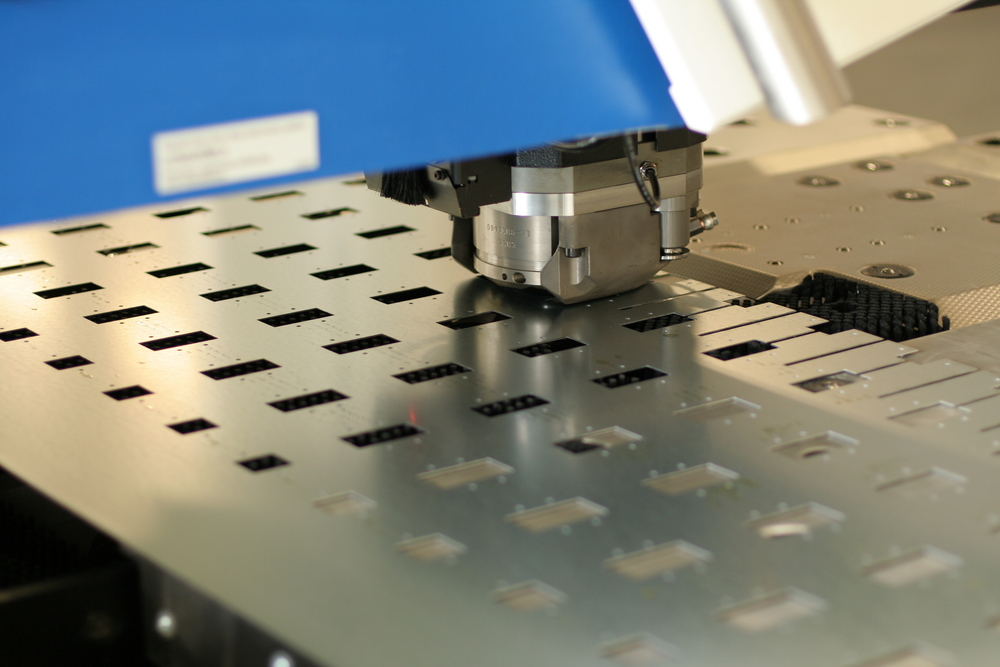

At its core, shearing is a slicing operation that entails using two blades to shear or separate materials, sometimes metallic, utilizing a excessive power. In a typical shearing course of, a fabric comparable to sheet metallic or plastic is positioned between two blades, which then apply strain to the fabric. The power exerted causes the fabric to fracture alongside an outlined line, making a clear minimize. This course of isn’t a easy act of slicing however entails a major quantity of strain, and the standard of the minimize relies upon closely on the sharpness of the blades, the fabric being minimize, and the alignment of the shearing machine.

The shearing course of is primarily used to chop skinny supplies like sheets and strips, nevertheless it may also be utilized to thicker supplies in additional industrial settings. The commonest shearing machines embrace guillotine shears, hydraulic shears, and mechanical shearing machines. These machines differ in the way in which they exert strain on the fabric, however the basic precept of shearing stays the identical.

The Mechanics Behind Shearing Machines

Shearing machine operations are subtle and contain a number of vital parts. On the coronary heart of the method is the shear blade, which is liable for making the minimize. These blades are typically fabricated from hardened metal to resist the strain and power utilized through the operation. They arrive in numerous styles and sizes, relying on the kind of shearing machine and the fabric being minimize. For instance, some shearing machines could use a straight blade, whereas others could use a rotary blade to deal with several types of materials.

The shearing course of operates by means of a shearing motion that happens when one blade strikes in the direction of a set blade, making use of power to the fabric in between. The fabric, being held in place, experiences this power till it reaches a degree the place it may possibly now not face up to the strain, inflicting it to fracture. This slicing motion is mostly a mix of shearing power and the geometry of the blade itself. By adjusting the hole between the 2 blades and the velocity at which they transfer, producers can management the standard and effectivity of the minimize.

In some shearing machines, hydraulic methods are employed to generate the power needed for slicing. These methods are extremely efficient, as they supply constant and managed power that may be fine-tuned relying on the thickness and hardness of the fabric. Then again, mechanical shearing machines use a system of gears and cams to generate power, making them less expensive however much less exact than their hydraulic counterparts.

Functions of Shearing in Machining

Shearing is a flexible operation with functions throughout a variety of industries. Within the metalworking trade, it’s primarily used to chop sheets, plates, and strips of metallic to dimension. As an example, within the automotive trade, shearing is used to create elements comparable to chassis, physique panels, and different parts that require exact, straight cuts. In aerospace manufacturing, shearing is crucial for slicing light-weight metals like aluminum to the required styles and sizes. Moreover, the method is essential for the fabrication of structural parts utilized in buildings and bridges.

Shearing can also be prevalent within the plastics trade, the place it’s used to chop plastic sheets, pipes, and profiles. The power to create clear cuts with out producing extreme warmth is important in guaranteeing that the structural integrity of the plastic is maintained. This additionally reduces the chance of deformities and stress fractures that will come up from different slicing strategies, comparable to grinding or sawing.

One other key software of shearing is in recycling operations. Supplies comparable to scrap metallic, paper, and plastic are sometimes minimize into smaller items to facilitate simpler dealing with, transportation, and processing. In such circumstances, large-scale shearing machines are employed to interrupt down these supplies into manageable sizes for additional processing and reuse. The shearing course of helps scale back waste and ensures that uncooked supplies are effectively utilized in varied industrial functions.

Benefits of Shearing in Machining

The shearing course of affords a number of vital benefits that make it a well-liked selection in varied manufacturing and manufacturing settings. One of many major advantages of shearing is its skill to ship exact and correct cuts, particularly relating to skinny supplies. Since shearing entails the applying of a centered power over a particular space, it produces clear edges and a excessive stage of dimensional accuracy. That is important for industries the place tight tolerances are required, comparable to aerospace and automotive manufacturing.

One other benefit of shearing is its velocity and effectivity. In contrast to different slicing processes like sawing or grinding, shearing can produce cuts rapidly, permitting for prime throughput in manufacturing environments. Shearing machines can deal with giant volumes of fabric with minimal downtime, making it an excellent selection for mass manufacturing and high-volume operations. Moreover, the truth that shearing doesn’t generate warmth means that there’s much less danger of fabric distortion or warping. This makes it notably well-suited for slicing supplies which might be delicate to temperature adjustments, comparable to plastics and metals with low melting factors.

Shearing additionally affords price benefits when it comes to each the equipment and the power required to carry out the cuts. Mechanical shearing machines, particularly, are comparatively cheap to buy and preserve in comparison with extra complicated slicing applied sciences like laser slicing or waterjet slicing. Moreover, since shearing sometimes requires much less power than different strategies, it’s a cost-effective possibility for producers seeking to streamline their manufacturing processes with out compromising on high quality.

Challenges and Limitations of Shearing

Regardless of its many benefits, shearing isn’t with out its limitations. One of many major challenges of the shearing course of is the potential for materials distortion, particularly when coping with thicker supplies or supplies with inconsistent hardness. Whereas the shearing course of can produce clear cuts, it might typically lead to burrs or edge deformation, notably if the shearing machine isn’t calibrated accurately or if the fabric is of poor high quality. To beat this, producers typically use secondary processes, comparable to deburring or grinding, to easy out the sides and make sure the desired end.

One other limitation of shearing is that it’s best fitted to slicing supplies of a sure thickness vary. Whereas it’s superb for skinny sheets or strips, it might wrestle with slicing thicker or tougher supplies. In these circumstances, different slicing strategies like plasma slicing, laser slicing, or water jet slicing could also be extra acceptable, as they will deal with a wider vary of fabric thicknesses and hardness.

Moreover, the design of the shearing machine and the kind of blades used can considerably influence the standard of the minimize. Machines with poorly maintained blades or improper blade alignment could result in inconsistent cuts, elevated put on, and frequent upkeep necessities. Guaranteeing that the shearing machine is well-maintained and the blades are sharpened repeatedly is crucial for optimizing the method and guaranteeing high-quality outcomes.

Conclusion

Shearing in machining is a vital course of that permits for the exact and environment friendly slicing of supplies, particularly in industries like metalworking, automotive, aerospace, and plastics. By understanding the mechanics, benefits, and limitations of shearing, producers could make knowledgeable choices about the perfect slicing methodology for his or her operations. As expertise continues to evolve, shearing machines and their capabilities will undoubtedly enhance, providing much more benefits when it comes to velocity, accuracy, and effectivity.

Want Metal Fabricators in Hermiston, OR?

NW Metallic Fabricators, Inc. is a family-owned enterprise that has been servicing clients in Hermiston, Oregon since 1986. We now have greater than 100 years of expertise within the food-processing trade and specialize within the customized manufacturing of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metallic Fabricators, Inc. is an accredited member of the native Chamber of Commerce. We’re a devoted enterprise the place high quality all the time comes first. Our clients know that they will depend on us to make it possible for their merchandise are hand-crafted to satisfy their specs. Contact us at present to study extra about what we are able to do for you!

Categorised in: Shearing

This submit was written by admin