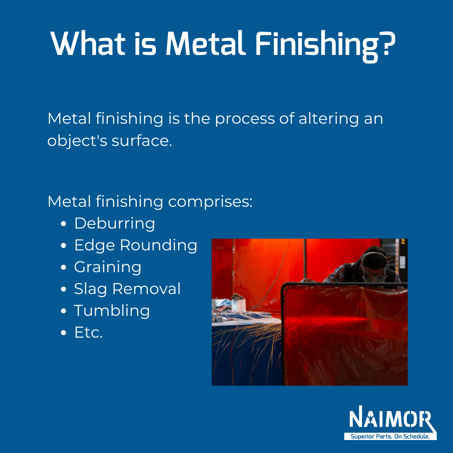

What’s Metallic Ending?

Metallic ending is the method of altering an object’s floor. The explanation for this course of is to enhance the looks of the meta. And to organize it for paint, powder coating, or different floor coatings. In some circumstances, it’s also used for bettering the sturdiness of the steel.

How Does Metallic Ending Work?

Metallic ending is without doubt one of the last procedures taken within the steel fabrication course of. It permits us to excellent our elements earlier than they attain clients.

There are a number of other ways to do steel ending, every providing their very own advantages. These processes embrace: deburr, edge rounding, graining, and slag removing machines.

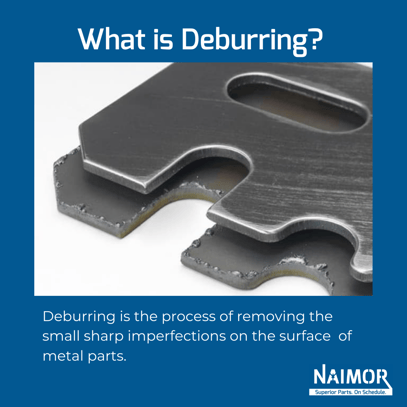

Deburring

Burrs are small, sharp imperfections on the perimeters and floor of elements and deburring is the method of eradicating these burrs. It’s a value efficient methodology of floor ending and produces a top quality end.

The most typical deburring machines for sheet steel are Timesaver sanders. They use a big sanding belt and a conveyor system to feed sheets by means of. There’s a peak adjustment for various materials thicknesses. A time save can course of a excessive quantity of sheets/elements rapidly because of the computerized feeding system that retains elements transferring.

Edge Rounding

Edge rounding removes the vertical burrs in addition to nibble marks or scallops on the holes and edges of an element that has already been deburred.

It’s also used to interrupt the sting on the processed elements. This permits for easy steel elements which makes with the ability to do excellent coating and safety considerably simpler.

Tumbling

In tumbling a batch of elements is put right into a rotating drum with media. The media might be sand, or different abrasive materials.

The elements, together with the media, are allowed to tumble within the machine for a set period of time to attain a softened rounded edge and a sturdy floor end. This course of is environment friendly as a result of as soon as the tumbler is loaded it runs with out an operator needing to face by.

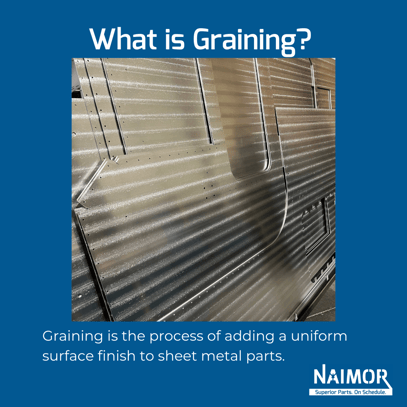

Graining

Graining is the method of including a uniform floor end to sheet steel elements.

Totally different measurement grit or various kinds of abrasives could also be used to create totally different graining results. A sheet of steel is handed by means of a belt sander on a conveyor belt and contained in the sander a belt coated with abrasive spins on two cylindrical drums.

A CNC router will also be used to grain sheet steel. It does this by swapping the software to a round metal brush. Which then runs over the floor of the steel to create the grain.

Industries which will use steel graining embrace house home equipment, aerospace, automotive, meals processing, equipment, {hardware}, leisure, and architectural.

Slag Removing

Slag is the by-product of chopping sure metals. If not eliminated earlier than the steel cools, the slag solidifies on high of your metal. Making your half tough across the edges and marked with burrs.

Among the finest methods to take away slag is with a particular machine. This machine is quicker and safer than utilizing angle grinders on an element.

Unfinished elements are fed by means of the machine. Which then runs elements by means of a excessive velocity drum after which a extremely versatile, diamond-profiled curler.

The curler rounds off the perimeters of elements as nicely. After the grinding portion is full, elements are then handed over by a high-density metal wire brush. This removes any remaining sharp edges.

Why Metallic Ending?

An element that accommodates burrs or slag is flawed. These imperfections compromise the performance, lifespan, and security of a machined half. They usually could cause quite a few high quality and look points.

Why NaiMor?

Do you know that steel ending can account for 30 to 35% of the guide labor prices?

Nonetheless, these prices are drastically diminished when a steel fabrication store invests within the specialised equipment required to effectively full totally different steel ending processes.

Now we have invested in a number of totally different specialised steel ending machines and due to this fact are capable of supply decrease labor prices, guarantee increased half high quality, and enhance employee security!

At NaiMor we satisfaction ourselves on our fast response instances and speedy manufacturing charges for all our completed elements. We additionally make use of operators who’ve a deep data base and abilities to match.

NaiMor ensures high tier work, all carried out in home. See our weblog put up for additional info on our steel ending companies!

Take a look at our instagram for a lot of extra pictures and movies of our work!