What’s a CNC Router?

The CNC Router is a slicing machine that’s managed by a pc numeric management unit. Take a look at our weblog publish for an summary of what CNC is.

The CNC processor controls the way in which the instruments transfer with a purpose to minimize and form the specified materials. The principle features are to chop, engrave, and carve objects out of supplies.

CNC routers aren’t designed to chop onerous metals like metal. They’re used to chop softer supplies akin to plastic, foam, and wooden. Some routers, like these right here at NaiMor, also can work with mushy metals, like aluminum, copper, and brass.

They’re additionally exceptionally quick, and may produce actual, correct, and complicated shapes and contours with a excessive diploma of repeatability.

CNC slicing machines might be spindle or router based mostly. Spindles and routers are related in that they’ll minimize a variety of supplies,utilizing a rotating cutter, but when more durable supplies are concerned, spindles are a greater possibility.

Compared to routers, spindle machines have higher bearings and are extra highly effective. This makes them extra exact and longer lasting. Spindle based mostly routers are additionally higher for slicing aluminum.

How Does the CNC Router Work?

CNC routers fluctuate of their construct, dimension, and configuration. They will have a number of axes to work with and the flexibility to swap instruments to carry out totally different duties.

The instruments are on a “carousel” which permits the machine to vary instruments on the fly. Which means there is no such thing as a stopping work to vary instruments when totally different ones are wanted for a person job.

With a view to maintain supplies on the slicing floor, NaiMor’s routers use a vacuum seal. Which means air is sucked down from the desk high to maintain supplies down. So even when components get minimize, they keep on the desk!

The important thing function of those machines is the pc management, which strikes, relates, and spins instruments based on a CAD/CAM program. CNC routers can are available many various sizes, together with desktop variations.

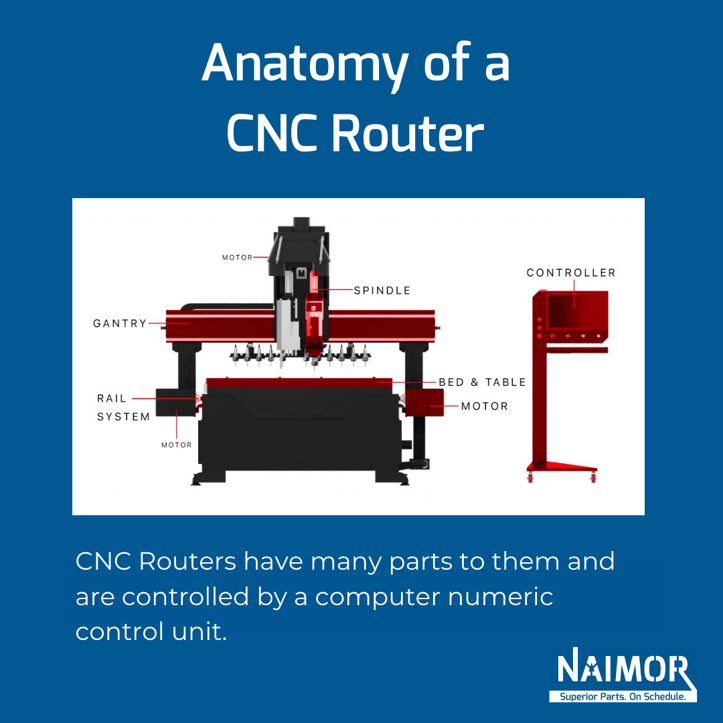

The core parts of a CNC Router are:

- Spindle: The slicing half. CNC spindles fluctuate based mostly on their slicing motion, cooling technique, and so on.

- Motor: Defines the performances of the router. Motors might be stepper motors or servo motors.

- Stepper motors brushless electrical motor. The stepper motor equally divides the total rotation into a number of steps.

- Servo motors are a part of closed loop techniques. Servo motors have their torque in addition to velocity guided by a servo controller. The servo controller makes use of a suggestions gadget to shut the loop.

- Desk: The CNC router desk holds the fabric being minimize. Tables are made of various supplies.

- Management System: The “mind” of the machine. They interpret CAD/CAM software program and execute g-code programming. This tells the machine how you can transfer and minimize.

- Movement Management Drive: CNC routers usually transfer throughout 3 axes with the assistance of a gantry: the x-axis, y-axis, and z-axis. Their motion defines the device path they want and the related motions (linear, rotary, and so on.) that help slicing.

- X-axis: entrance to again motions. That is often the longest.

- Y-axis: the left to proper motion.

- Z-axis: the up and down motion.

Why Do We Use a CNC Router?

Pc managed routers assist to cut back manufacturing time and manufacturing errors as a result of their excessive pace, larger accuracy, and diminished waste. They’re a most popular alternative of half slicing for industries the place they’re involved with the warmth affected zone on laser minimize edges.

This results in elevated manufacturing capability and decrease prices for our prospects. All of which could be a important concern whereas producing excessive precision jobs.

Purposes for CNC routers help a number of markets:

- Aerospace

- Protection

- Textile

- Medical

- Digital sectors

- Automotive

- HVAC

- Laundry

- Lighting

- Cryogenics

- Refrigeration

- Renewable power

- Know-how

Why NaiMor?

At NaiMor we pleasure ourselves on our fast response instances and speedy manufacturing charges for all our completed components. We additionally make use of operators who’ve a deep data base and expertise to match.

At NaiMor we have now two routers: one with a slicing floor of 60” x 144” and one other at 96” x 360.

NaiMor ensures high tier work, all finished in home. See our weblog publish for additional data on our CNC router providers!

Take a look at our instagram for a lot of extra pictures and movies of our work!