Our mission to mix experience and know-how to ship unmatched precision and high quality in each venture. Just lately, our staff deepened its mastery of tube laser chopping by attending superior coaching on the headquarters of BLM Group, the producer of our state-of-the-art LT8.20 tube laser chopping machine. This intensive studying expertise revealed thrilling methods to optimize programming and maximize the capabilities of this superior machine. The end result? Larger effectivity, superior high quality, and progressive options for our clients.

Listed here are 5 methods of how we leverage the total potential of our tube laser cutter to make sure your customized fabrications are in skilled palms.

Instance 1: Band Noticed vs. Tube Laser

Conventional strategies like band noticed chopping have lengthy been staples of fabrication, however the LT8.20 tube laser transforms what’s potential.

Conventional strategies like band noticed chopping have lengthy been staples of fabrication, however the LT8.20 tube laser transforms what’s potential.

For structural elements requiring straight cuts, the tube laser performs these operations far quicker than a band noticed, whereas eliminating the damage and tear of noticed blades. It doesn’t cease at straight cuts. With the tube laser, we are able to create advanced options like chamfered or curved holes instantly in a bit of pipe. As an illustration, we are able to reduce a slot, insert one other piece of fabric, and put together it for welding—multi functional seamless course of.

In distinction, a band noticed would require a number of steps, together with chopping, drilling, and extra prep work. By streamlining operations with the tube laser, we not solely save time but additionally ship precision that handbook processes merely can’t match.

Instance 2: Many Options in a Single Tube

In lots of tasks, a single tube could require a number of distinct options. For instance, a sq. tube would possibly want two massive openings on reverse sides, together with smaller options elsewhere.

Our tube laser permits us to strategically sequence these cuts. First, we reduce one characteristic, transfer the tube ahead, and reduce the subsequent. Then, we return to the preliminary facet to finish the remaining options. This strategy minimizes warmth buildup, prevents materials warping, and ensures clear, exact cuts each time.

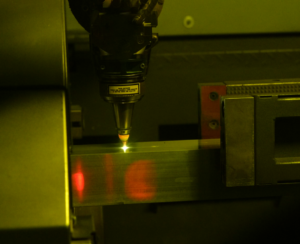

Instance 3: Allow Lively Tilt

One standout characteristic of the LT8.20 is its skill to tilt the chopping head by greater than 15 levels whereas concurrently rotating the workpiece. This functionality allows us to supply options that might be unimaginable to chop on much less subtle machines.

One standout characteristic of the LT8.20 is its skill to tilt the chopping head by greater than 15 levels whereas concurrently rotating the workpiece. This functionality allows us to supply options that might be unimaginable to chop on much less subtle machines.

Lively tilt know-how optimizes the chopping course of for advanced geometries, resembling angled cuts and complex beveled edges. This stage of precision ensures that your elements are prepared for meeting, lowering the necessity for secondary processing.

Instance 4: Optimized Finish Piece Cuts

Creating clear and purposeful finish cuts is essential for structural assemblies like handrails or customized frames. The tube laser excels at producing curved cuts that match collectively like puzzle items.

This strategy eliminates the necessity for cumbersome fixtures and clamps throughout welding. By enhancing the match and end of those joints, we are able to speed up meeting instances and enhance the general structural integrity of the ultimate product.

Instance 5: Mechanically Sorting Elements and Scrap

Effectivity extends past chopping. Our LT8.20 is supplied with superior conveyors that separate brief elements from scrap materials mechanically.

Even when elements and scrap are comparable in dimension, the machine’s programming ensures correct sorting. This characteristic not solely reduces handbook labor but additionally retains operations operating easily, permitting us to take care of quick turnaround instances whereas minimizing waste.

Why Select Ameritex for Tube Laser Chopping?

Optimizing our tube laser chopping providers is only one instance of how Ameritex applies its deep experience in customized steel fabrication to ship excellent outcomes. By repeatedly refining our processes and staying on the forefront of fabrication know-how, we make sure that your tasks are dealt with with the utmost care and precision.

Whether or not you’re designing elements with intricate options or want environment friendly manufacturing of structural assemblies, our staff is able to flip your imaginative and prescient into actuality.

Able to take your venture to the subsequent stage? Contact us at the moment to study extra about our capabilities, or request a quote to see how Ameritex can carry precision and effectivity to your subsequent venture.