Like many firms, Miller Fabrication Options more and more acknowledges the significance of following sound environmental practices. We persistently work to attenuate our environmental influence whereas delivering superior options to our OEM purchasers.

Listed here are key initiatives and achievements that display our environmental dedication:

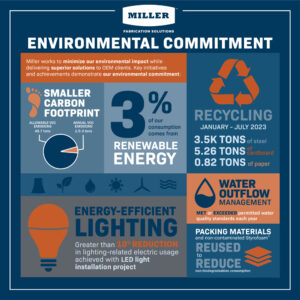

Smaller Carbon Footprint

Our gasoline utilization, VOC and carbon emissions information illustrate our dedication to lowering our carbon footprint. Whereas our emissions allow permits for the discharge of 49.7 tons of VOC yearly, for instance, our use of powder coatings limits our emissions to only 2.5 to three tons. Our profitable efforts to scale back emissions is testomony to our ongoing sustainability efforts.

Embracing Renewable Vitality

Each time we are able to fairly accomplish that, we harness power from renewable sources to gas our operations. Now we have established a long-term settlement with our power supplier to make sure a gentle provide of renewable power, which at present accounts for roughly 3% of our consumption.

Water Outflow Administration

Preserving the standard of water sources is necessary to us. In any respect our amenities, we maintain stormwater launch permits and accumulate the required runoff samples twice a yr. These samples endure rigorous third-party laboratory evaluation, and the information is reported to the Pennsylvania Division of Environmental Safety (PA DEP). We persistently meet or exceed the water high quality requirements outlined in our permits, reflecting our dedication to sustaining clear water outflows.

Efficient Recycling Applications

Miller has carried out sturdy recycling applications to scale back waste and promote sustainability. In 2023 alone, now we have up to now recycled a formidable 3,515 tons of metal, 5.26 tons of cardboard and 1,640 kilos of workplace paper. Moreover, we prioritize the reuse of non-contaminated Styrofoam and packing supplies, thereby lowering the consumption of those non-biodegradable supplies.

Environmentally Pleasant Coatings and Chemical compounds

We’re devoted to utilizing environmentally pleasant paints and chemical substances in our manufacturing processes. Prior to buy or supply, we totally assessment all coatings and chemical substances to make sure compliance with the stringent environmental requirements set forth by the PA DEP. Our dedication extends to monitoring and reporting using these substances, together with VOCs, carbon dioxide and different doubtlessly dangerous compounds. By adhering to those requirements, Miller helps make sure the well-being of our staff, our communities and the atmosphere.

Vitality Effectivity via LED Lighting

To realize larger power effectivity, we accomplished an LED gentle set up challenge throughout all our amenities. This initiative has resulted in a larger than 10% discount in lighting-related electrical utilization. Not solely are we saving power and lowering prices, but additionally the improved lighting enhances the general work atmosphere, contributing to high quality and worker security.

Assembly European Requirements

Elements we produce for some clients are required to fulfill European requirements. We meticulously assessment all chemical substances to make sure compliance with these laws, which are sometimes stricter than U.S. requirements. This dedication allows our clients to fulfill their environmental obligations and promote their merchandise in Europe and america.

Miller’s efforts replicate our dedication to stewardship and environmentally pleasant manufacturing practices. From minimizing carbon emissions and embracing renewable power, to rigorous water administration and efficient recycling applications, we’re dedicated to accountable practices that contribute to a more-sustainable future.