Correct flat patterns are important for creating high-quality, dependable sheet metallic components that match completely into your designs. At Ameritex, we perceive that the bending course of can introduce distinctive challenges, because the metallic compresses on the within of a bend and stretches on the surface. With out accounting for these modifications, components could not meet your specs, resulting in delays or rework.

Ok-Issue is a important instrument we use to make sure precision in flat sample improvement. By understanding how metallic behaves below bending stress, we calculate dimensions with pinpoint accuracy, delivering components that carry out as anticipated each time. Whether or not you’re designing for tight tolerances or complicated assemblies, the Ok-Issue performs a key position in getting it proper the primary time.

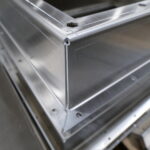

- Bent sheet metallic body utilizing the Ok-Issue to make sure high quality

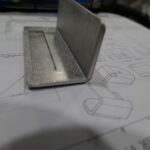

- Light-weight precision: skinny sheet metallic half with sharp, intricate bends

- Precision-engineered skinny sheet metallic half with intricate angles, crafted for distinctive accuracy

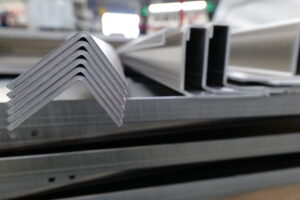

- Good precision: A sheet metallic bracket bent at a 90-degree angle for superior structural integrity

Creating an correct flat sample for a sheet metallic fabrication undertaking requires understanding how bending deforms the fabric. Through the bending course of, the metallic compresses on the within of the bend and stretches on the surface. Because of this, exact calculations are essential to account for this deformation when figuring out the flat sample—the 2D structure of the half earlier than bending.

Merely including up the physique and flange dimensions of an element gained’t yield correct outcomes, as this method overlooks how the fabric stretches throughout bending. That’s the place the Ok-Issue is available in. This mathematical property supplies important perception into how metallic behaves below bending stress, enabling the event of exact flat patterns.

What’s Ok-Issue?

The Ok-Issue is a key aspect in precision sheet metallic fabrication and represents the ratio between the placement of the impartial axis and the fabric thickness. The impartial axis is a theoretical line throughout the materials the place there isn’t any stress or compression throughout bending. This line performs a important position in figuring out the correct size of the metallic in its flat kind, as the fabric on this axis doesn’t elongate or compress.

Medium-thickness sheet metallic half designed for industrial sturdiness bent at 90 diploma angle

In mathematical phrases, the Ok-Issue is a dimensionless worth ranging between 0 and 0.5 for many metallic fabrication companies. This worth will depend on a number of components, together with materials sort, thickness, and the radius of the bend:

• Ok = 0: This might imply the impartial axis is on the outer floor of the bend, a situation that’s virtually unimaginable as a result of all supplies expertise some extent of inside stress and compression.

• Ok = 0.5: This means that the impartial axis is exactly midway by means of the fabric thickness. Though this situation can be uncommon, it’s extra prone to happen in softer supplies or when utilizing bigger bend radii.

The method for calculating the Ok-factor in sheet metallic bending is Ok = t/MT, the place:

Ok: The Ok-factor

t: The centerline thickness within the bend

MT: The beginning materials thickness

For sensible purposes in customized metallic fabrication, Ok-Issue values typically vary from 0.3 to 0.5, relying on particular materials traits and bending necessities.

The Ok-Think about Apply

The Ok-Think about Apply

Whereas the theoretical Ok-Issue affords an preliminary start line, materials properties and bending tools introduce variances. To attain the utmost precision with our flat patterns, at Ameritex we take a look at the theoretical Ok-Issue by means of pattern bends. To take action, we carry out pattern bends and measure any discrepancies with the supposed dimensions. These exams assist us decide the sensible Ok-Issue, which can differ barely as a consequence of materials sort, thickness, and bending tools settings. Figuring out the sensible Ok-Issue is crucial for reaching the tightest tolerances, making certain that every half meets exact specs for match and performance in complicated assemblies.

As soon as we’ve established the Ok-Issue for a particular set of parameters—like materials thickness, bend angle, and die dimension—we will apply this worth persistently below the identical circumstances in future initiatives. Nonetheless, the calculation strategies could fluctuate throughout totally different tools. As an example, our LVD ToolCell press brake makes use of a way often called bend deduction, which might be derived from the Ok-Issue.

Different machines, just like the VaskiPUNCH and Euromac Digibend, used for copper fabrication companies, immediately use the Ok-Issue. This method is efficient for supplies like copper, the place maintaining a constant thickness and bend angle permits us to depend on a hard and fast Ok-Issue worth. For instance, if we’re bending copper with a ¼” thickness with the identical bend angle, the Ok-Issue stays fixed, making certain excessive accuracy for all related initiatives.

Your Trusted Provider for Shaped Steel Elements

Ameritex combines skilled data in customized metallic fabrication with superior tools to offer high-quality outcomes for each undertaking. Our group has intensive expertise in metallic forming, chopping, welding, and ending, making us a dependable associate for complicated and exact metallic elements. No matter your undertaking’s necessities, we’re right here to fulfill your specs with top-tier experience and the newest in fabrication know-how.

Contact us in the present day to debate your undertaking or request a quote. Ameritex is dedicated to delivering high quality, consistency, and precision in each half we produce.