Ameritex is understood for showcasing our large-scale tasks like fabricated buildings and customized enclosures. Whereas these spectacular tasks spotlight our power in customized steel fabrication, what usually goes unnoticed is the important function intricate and complicated components play in bringing these bigger assemblies collectively. Many tasks depend on precision elements with tight tolerances to make sure seamless performance and long-term reliability.

At this time, we’re diving into our superior milling and tapping capabilities, which permit us to ship exceptionally detailed elements, making certain each half—regardless of the dimensions—meets your actual wants with unparalleled accuracy.

Past Laser Slicing: The Position of Milling in Precision Fabrication

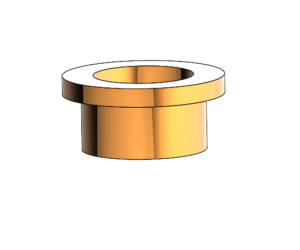

With regards to intricate geometries, chopping alone doesn’t at all times present the superb particulars wanted. That’s where milling steps in. Milling is a subtractive manufacturing course of the place rotating instruments take away materials from the workpiece, shaping and contouring it to create advanced and exact options. At Ameritex, our experience in each CNC milling and CNC lathing permits us to tackle even probably the most intricate jobs, making certain clean surfaces, tight tolerances, and clear edges.

Sorts of Milling for Completely different Geometries

Relying on the half’s necessities, we use several types of milling strategies to attain particular shapes and finishes:

Face Milling: This system includes chopping alongside the face of the workpiece, making a flat, uniform floor. It’s perfect for getting ready surfaces earlier than extra intricate cuts are made.

Face Milling: This system includes chopping alongside the face of the workpiece, making a flat, uniform floor. It’s perfect for getting ready surfaces earlier than extra intricate cuts are made.- Finish Milling: One of the vital versatile milling processes, finish milling permits us to make deep cuts, and cavities, and create advanced holes or shapes. That is good for components that require detailed inside geometries or angled cuts.

- Slot Milling: Creating grooves or channels in a bit is crucial for a lot of mechanical components, and slot milling is the go-to methodology for these cuts. Whether or not it’s for structural functions or to create paths for fasteners or connectors, this system ensures tight and constant slots.

- Peripheral Milling: When the perimeters of the half must be completed to exacting requirements, peripheral milling ensures a clean, clear reduce alongside the outer edges of the piece.

Our CNC mills and lathes give us the potential to work with excessive precision throughout a variety of supplies, together with aluminum, chrome steel, and extra. Whether or not your components want primary contours or extremely detailed profiles, our milling experience ensures each mission is accomplished with unmatched accuracy.

Creating Threads with Precision: The Tapping Course of

Simply as intricate cuts require milling, many customized components require tapping to create threaded holes or options. Tapping is the method of chopping threads right into a pre-drilled gap, permitting screws or bolts to lock securely. At Ameritex, we make use of each machine tapping and hand tapping to make sure your components are threaded with precision, consistency, and uniformity.

Sorts of Tapping for Completely different Purposes

Machine Tapping: Carried out on a CNC machine, machine tapping is ideal for high-precision work. It ensures that every thread is uniform, precisely positioned, and on the appropriate depth—notably vital for important components that want to carry up below stress or movement.

Machine Tapping: Carried out on a CNC machine, machine tapping is ideal for high-precision work. It ensures that every thread is uniform, precisely positioned, and on the appropriate depth—notably vital for important components that want to carry up below stress or movement.- Hand Tapping: Typically, the geometry of a component makes machine tapping troublesome—particularly if a gap is simply too near a bend or in a hard-to-reach space. In these circumstances, hand tapping is carried out after the piece has been formed, permitting us to fastidiously and exactly reduce threads in spots the place machines can’t attain.

- Backside Tapping: For blind holes that don’t go all over a bit, backside tapping is used to create threads on the backside of a gap, permitting for safe fastening with out penetrating by the fabric.

Threaded holes must be completely exact to make sure correct fastening and longevity. That’s why we apply our tapping experience to ship constant outcomes, saving our clients time and making certain every half is able to use as quickly because it arrives.

Combining Experience for the Most Advanced Elements

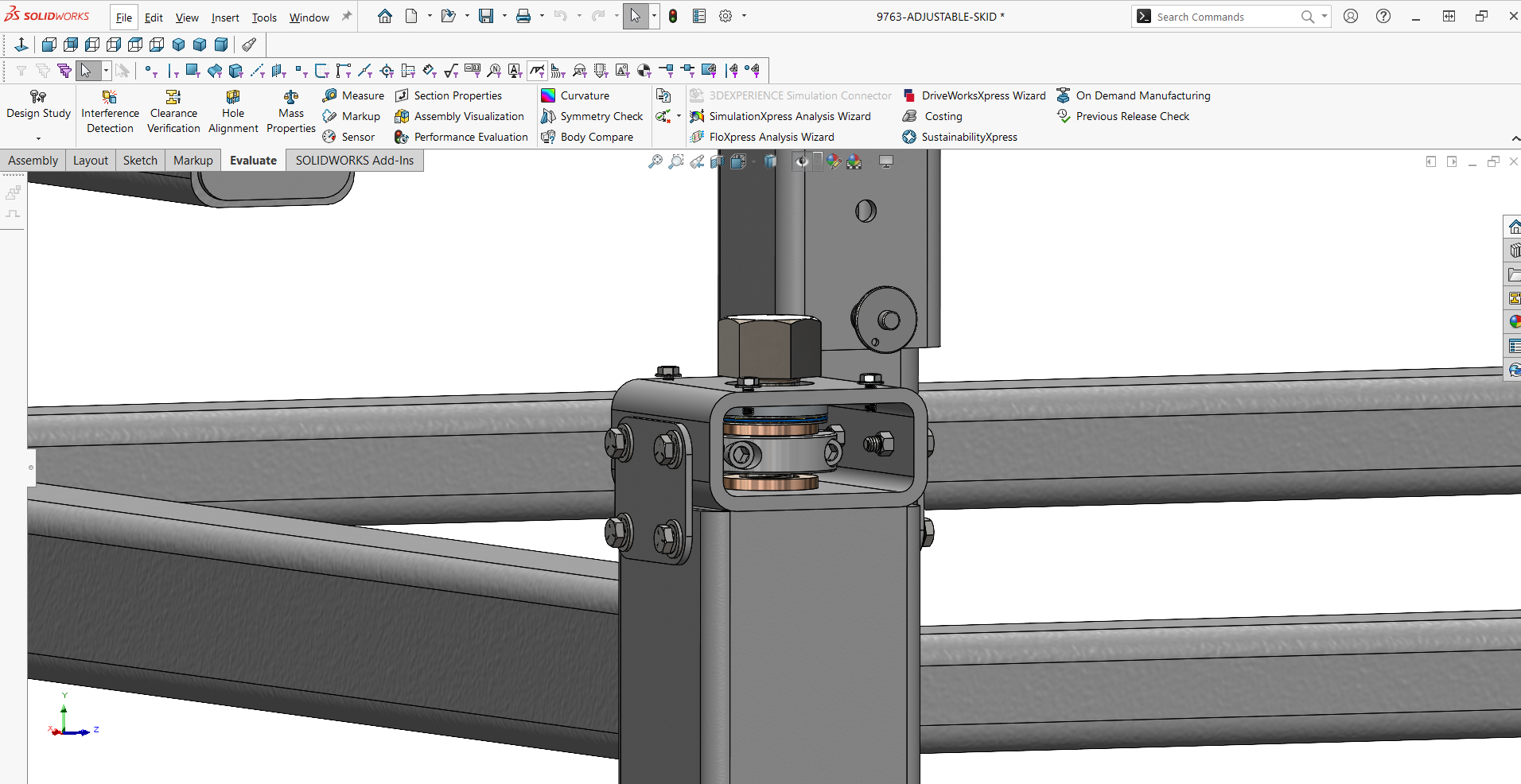

At Ameritex, we don’t simply cease at one course of—we mix our data of laser chopping, punching, forming, milling, and tapping to create components that meet your actual wants. Intricate geometries usually require a number of processes, and our potential to seamlessly combine these strategies permits us to deal with even probably the most difficult tasks.

For instance, a mission could begin with laser chopping to outline the general form, however to satisfy the tolerance necessities, milling could also be used to clean out sure edges or create superb options. Then, tapping is added to create threaded holes, making certain the half is prepared for meeting. Whether or not it’s a customized door, an enclosure with advanced inside geometry, or a specialised bracket, our strategy ensures precision at each stage of manufacturing.

Companion with Ameritex for Precision Fabricated Elements

At Ameritex, we all know that attaining intricate geometries with tight tolerances requires extra than simply the fundamentals. From idea to completion, Ameritex is your trusted accomplice in customized steel fabrication, delivering top-tier merchandise tailor-made to your specs. In the event you want intricate components with exact tolerances, look no additional—our group has the instruments and know-how to show your concepts into actuality. Request a quote immediately!