August 9, 2025 3:55 pm

Precision machining is a vital part of recent manufacturing, enabling the creation of elements and elements that adhere to actual specs. From aerospace to medical gadgets, the flexibility to craft intricate elements with exceptional consistency and accuracy dramatically influences the standard of the ultimate product. Whereas conventional machining methods have served industries for many years, excessive tolerance machining is now a cornerstone of high quality assurance and efficiency excellence. On this article, we discover how precision machining enhances the ultimate product high quality throughout varied sectors and why producers more and more make investments on this superior functionality.

Understanding Precision Machining and Its Capabilities

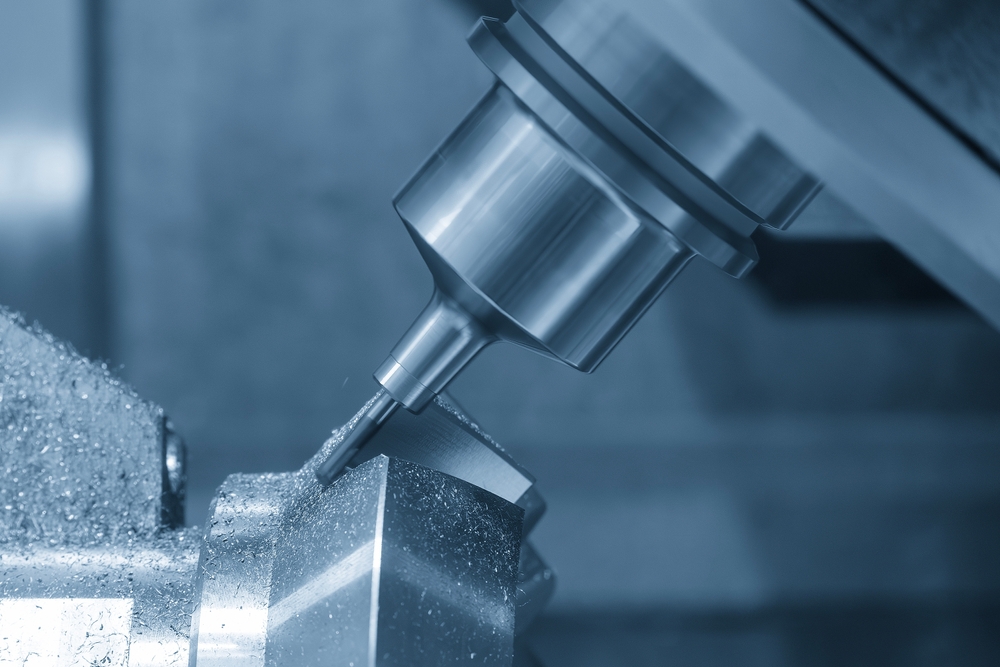

Precision machining refers back to the technique of eradicating materials from a workpiece to create elements that meet very particular design tolerances—usually inside thousandths of an inch. The time period encompasses quite a lot of superior methods and instruments similar to CNC (Laptop Numerical Management) milling, turning, grinding, and electrical discharge machining (EDM). These strategies are able to producing elements that conform to actual blueprints with minimal variability.

The power of precision machining lies in its capability to realize excessive repeatability and element even in advanced geometries. That is particularly crucial for industries like aerospace, automotive, electronics, and healthcare, the place the efficiency and security of finish merchandise rely closely on the precision of every half. Excessive tolerance machining permits producers to fulfill stringent design standards that might be inconceivable with guide or much less refined machining processes.

The advantages of precision machining lengthen past mere accuracy. It reduces materials waste, lowers operational prices in the long term, and considerably improves time-to-market resulting from minimized rework and tighter manufacturing controls. With digital integration and automation, precision machining now performs an important function in good manufacturing environments, selling constant output and streamlined workflows.

Enhancing Part Match and Performance

Probably the most rapid ways in which precision machining improves closing product high quality is thru superior part match and performance. In assembly-based merchandise, even a minor dimensional deviation in a single part can compromise the integrity and efficiency of your complete system. Excessive tolerance machining ensures that every half is manufactured inside the tightest specs, permitting for seamless meeting and dependable operation.

In mechanical assemblies, exact matches cut back friction, put on, and mechanical play, all of which might contribute to long-term degradation. In purposes similar to engines or gear methods, misalignment or extra clearance can result in elevated vibration, noise, and untimely failure. Precision-machined elements remove these points, enhancing each the short-term efficiency and longevity of the product.

Moreover, merchandise that rely upon fluid or gasoline switch—like hydraulic methods or medical pumps—require elements with extraordinarily correct dimensions to make sure tight seals and controlled circulation. Precision machining permits producers to create these excellent matches, which in flip improves effectivity and prevents leakage, contamination, or system failure.

Bettering Product Reliability and Security

Reliability and security are paramount in crucial industries similar to aerospace, protection, and medical know-how. In these sectors, any failure—irrespective of how small—can result in catastrophic penalties. Precision machining enhances product high quality by minimizing variability and guaranteeing constant efficiency, which is crucial for assembly stringent trade rules and requirements.

For instance, within the aerospace sector, turbine blades, touchdown gear elements, and structural helps should not solely carry out beneath excessive circumstances but in addition bear rigorous certification. With the advantages of precision machining, producers can produce these elements with microscopic accuracy, guaranteeing uniformity and structural integrity. Likewise, within the medical discipline, implants and surgical devices should adhere to tight tolerances to make sure affected person security and efficient remedy. A deviation of even a number of microns may lead to gadget malfunction or compatibility points inside the human physique.

Excessive tolerance machining additionally performs a pivotal function in non-destructive testing (NDT) and high quality assurance workflows. Since elements are produced with such consistency, deviations from customary measurements are simpler to detect, permitting for extra environment friendly and correct inspection processes. This proactive strategy minimizes the chance of faulty merchandise reaching finish customers and helps a tradition of high quality from the bottom up.

Supporting Innovation and Advanced Design Implementation

As product designs develop into more and more refined, the necessity for superior manufacturing capabilities grows. Precision machining permits designers and engineers to push the boundaries of innovation with out being constrained by manufacturing limitations. Intricate geometries, micro-scale options, and customized configurations are all achievable because of the advantages of precision machining.

Superior supplies—similar to titanium, Inconel, and specialised polymers—usually require machining beneath strict course of controls to stop warping, cracking, or lack of materials integrity. Precision machining applied sciences are uniquely suited to deal with such necessities. This functionality permits producers to undertake cutting-edge supplies that improve product efficiency, whether or not by means of weight discount, thermal resistance, or chemical sturdiness.

Furthermore, in prototyping and R&D, precision machining accelerates product growth cycles. Engineers can iterate shortly, producing a number of design variations with constant high quality and precision. This not solely facilitates experimentation and refinement but in addition shortens the trail from idea to market-ready product.

As industries transfer towards mass customization, the function of excessive tolerance machining turns into much more very important. It permits producers to effectively produce small batches or one-off elements that meet the identical rigorous requirements as mass-produced gadgets. This flexibility permits firms to cater to area of interest markets or quickly altering buyer calls for with out compromising on high quality.

Driving Lengthy-Time period Price Effectivity and Sustainability

Whereas the upfront funding in precision machining tools and expert labor could also be excessive, the long-term monetary and environmental returns are substantial. Excessive tolerance machining reduces materials waste by optimizing reducing paths and eliminating the necessity for extreme ending or rework. This lean manufacturing strategy not solely conserves uncooked supplies but in addition reduces vitality consumption and power put on, contributing to a extra sustainable manufacturing course of.

From a value perspective, the advantages of precision machining manifest by means of diminished failure charges, decrease returns and guarantee claims, and decreased downtime in downstream operations. Merchandise that meet specs the primary time require fewer changes and inspections, resulting in smoother manufacturing cycles and quicker supply timelines. This reliability in manufacturing contributes to stronger model repute and buyer satisfaction.

Moreover, as producers undertake extra environmentally aware practices, precision machining aligns nicely with targets for minimizing scrap and optimizing useful resource utilization. Improvements similar to dry machining, coolant recycling, and additive-subtractive hybrid methods additional improve the sustainability profile of precision machining operations.

In a world more and more centered on lifecycle value and environmental impression, the benefits of precision machining transcend technical superiority. They create a basis for accountable manufacturing that balances efficiency, high quality, and ecological stewardship.

Conclusion

Precision machining stands as a crucial enabler of high-quality, high-performance merchandise throughout just about each main trade. Its means to ship elements with microscopic accuracy and distinctive consistency straight impacts product performance, security, and market readiness. The advantages of precision machining lengthen past the store ground—supporting innovation, enhancing sustainability, and decreasing long-term prices.

By embracing excessive tolerance machining, producers not solely meet the rising calls for of recent shoppers but in addition future-proof their operations in an more and more aggressive and quality-driven world market. Whether or not crafting aerospace elements or biomedical gadgets, precision machining stays the gold customary for excellence in manufacturing.

Want Metal Fabricators in Hermiston, OR?

NW Steel Fabricators, Inc. is a family-owned enterprise that has been servicing prospects in Hermiston, Oregon since 1986. We’ve got greater than 100 years of expertise within the food-processing trade and specialize within the customized manufacturing of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Steel Fabricators, Inc. is an accredited member of the native Chamber of Commerce. We’re a devoted enterprise the place high quality at all times comes first. Our prospects know that they’ll rely on us to be sure that their merchandise are hand-crafted to fulfill their specs. Contact us immediately to be taught extra about what we are able to do for you!

Categorised in: Machining

This put up was written by admin