Most imagine that excellence is a vacation spot, not a journey. We expect the alternative, as a result of we all know that excellence is a lifelong journey and a precept that we observe each single day.

Our dedication to fixed enchancment is woven into each side of our operations. By refining our processes, increasing our data, and leveraging superior applied sciences we cut back downtime, improve worker security, and ship high-quality merchandise to our clients.

Under, we’ll stroll you thru how Ameritex Machine & Fabrication stays forward within the customized steel manufacturing business by enhancing work directions, enhancing upkeep procedures for our machines, and creating strong inside academic content material for our staff.

New Course of for Store Flooring Work Directions

Being a job store by nature each undertaking on our store flooring is a chance to be taught, adapt, and enhance. To make sure precision and repeatability, we’ve applied a structured system to doc and tackle points encountered throughout manufacturing runs.

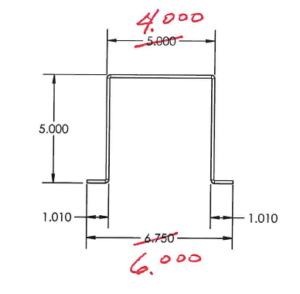

As an illustration, when working a tube laser reducing operation, we generally encounter prints that lack a view displaying the right place of the holes. With out this info, verifying the half throughout inspection turns into difficult, slowing down fabrication and growing prices. Equally, in our fabrication space, unclear welding symbols or sequences in prints can require extra consideration.

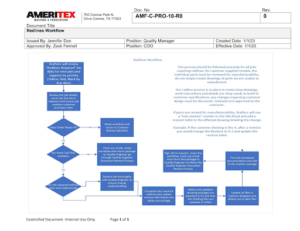

To unravel these points, we redline every drawing or specification that requires clarification. This ensures that the findings from the primary run of components are utilized to all subsequent runs. Past digital documentation, we additionally use bodily sheets that includes pictures of recognized points. These sheets are stored on the store flooring, and operators are required to assessment and log off on them earlier than beginning work.

This meticulous method ensures readability for operators and results in higher-quality outcomes for our clients.

Improved Autonomous Upkeep for Our Machines

Minimizing downtime is important in manufacturing, and as such we’ve applied proactive options to maintain our machines working easily.

One instance includes the conveyor system that works alongside our sheet lasers to take away scrap components robotically throughout reducing. Over time, we observed these conveyors may get clogged, inflicting delays and inefficiencies. To handle this, we applied a easy however efficient upkeep process: operators now carry the security door in a selected means (solely when the laser is powered down) to wash out scrap steel.

This transformation, although seemingly small, has considerably decreased downtime and materials waste whereas enhancing general operational effectivity. By frequently monitoring machine efficiency and discovering methods to streamline upkeep, we guarantee our gear delivers constant outcomes for our clients.

Persevering with Training and Coaching

At Ameritex, we perceive that investing in our staff is among the most impactful methods to enhance our processes and outcomes. To this finish, we’ve employed a studying specialist to create complete coaching supplies for our workers.

Ameritex’s workflows for figuring out Redlining

Our inside academic content material contains movies, tutorials, and programs designed to onboard new personnel and improve the talents of present staff members. These sources cowl important subjects like working lasers, press brakes, and punch presses, beginning with introductory programs and increasing into intermediate and superior ranges.

For instance, somebody new to our staff can start with foundational data and progress to mastering advanced machine operations. This ensures consistency, fosters a tradition of studying, and empowers our staff to carry out at their finest.

Main the Trade with Steady Enchancment

Our dedication to course of enchancment isn’t nearly optimizing operations—it’s about exceeding expectations. From refining store flooring practices to implementing smarter upkeep routines and empowering our staff with data, each step we take is geared toward delivering distinctive worth to our clients.

As we transfer ahead, our focus stays steadfast: combining precision, innovation, and a dedication to excellence to set the usual in customized steel fabrication. Allow us to present you the way every enchancment could make your subsequent undertaking seamless and profitable.

Able to see the Ameritex distinction? Contact us at this time to debate your subsequent undertaking or request a quote.