Ameritex Machine & fabrication specializes within the design and fabrication of customized skids (and different massive structural fabrications) that meet the precise specs of our clients. Whether or not you might have detailed CAD drawings, a photograph of a earlier skid you’d like to duplicate, or only a normal concept of what you want, our crew is able to convey your imaginative and prescient to life. With many years of expertise and a dedication to precision, Ameritex ensures that each customized skid is constructed to carry out reliably, irrespective of the appliance or atmosphere.

How Are Skids Constructed?

How Are Skids Constructed?

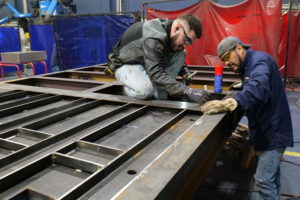

The development of skids begins with a sturdy framework, usually comprised of structural metal members reminiscent of C channels, I beams, or L angles. These parts kind the skeleton of the skid, offering energy and stability to deal with heavy masses and demanding environments. On high of the framework, a number of sheet steel plates are added to create a strong platform floor. Relying on buyer necessities, these plates could also be stitch-welded to the body or designed to be detachable for added flexibility.

Materials Selections

Most skids are fabricated from ASTM A36 metal, a flexible carbon metal generally utilized in industrial functions. In some instances, clients request a full stainless-steel pores and skin for environments with excessive publicity to moisture or chemical substances.

{Hardware} Specs

{Hardware} selections additionally rely upon the skid’s meant use and atmosphere. Choices embody stainless-steel and hot-dip galvanized {hardware} to make sure longevity and efficiency. By deciding on the appropriate mixture of supplies and development strategies, Ameritex delivers skids that meet the very best requirements of sturdiness and reliability.

Design Issues for Customized Skid Fabrication

Customized skid fabrication requires cautious consideration of a number of crucial components. At Ameritex, we take a consultative strategy to make sure that each element is accounted for, from structural integrity to environmental suitability.

Environmental Circumstances and Load Necessities

One of many first design issues is the atmosphere the place the skid will likely be used. Skids uncovered to harsh outside situations might require specialised coatings or supplies to stop corrosion. Moreover, the skid should be designed to face up to the masses it’s going to bear. Prospects usually present load necessities, reminiscent of a most weight capability of 1,500 kilos. For added assurance, we are able to collaborate with skilled engineers (PEs) to validate the design and supply signed-off drawings that certify the skid’s load-bearing capabilities.

Precision and Match

Precision is essential in customized skid fabrication, particularly when mounting gear that requires precise alignment. For instance, motors or pumps usually have to be positioned inside tight tolerances to make sure correct operation. Our crew’s deep experience permits us to compensate for materials deflection and different variances. For example, I-beams can exhibit deflection starting from 1/16” to almost 3/8” from the online to the highest of the beam. By accounting for these deviations throughout fabrication, we guarantee an ideal match and seamless meeting.

Customized Options and Flexibility

We perceive that no two skids are alike. Prospects might require distinctive options reminiscent of particular {hardware} placements, detachable plates, or specialised coatings. Our versatile design course of permits us to include these customizations effectively, delivering a skid tailor-made to the precise wants of the challenge.

Customized Skids, Constructed to Your Actual Specs

At Ameritex, we satisfaction ourselves on our means to show our clients’ concepts into actuality. The important thing to a profitable challenge lies in clear communication and collaboration. We work carefully with our shoppers to grasp their necessities and supply detailed suggestions all through the design course of. From preliminary ideas to last fabrication, we make sure that each skid is constructed to attain its meant goal.

The extra particulars you’ll be able to present about your challenge, the higher we are able to tailor the design to fulfill your wants. Whether or not you’re specifying supplies, {hardware}, or distinctive design options, our crew is right here to information you each step of the best way. With Ameritex, you’ll be able to belief that your customized skid will likely be fabricated to the very best requirements of high quality and precision.

Prepared to begin your subsequent customized steel fabrication challenge? Contact us right this moment to learn the way Ameritex can ship the customized skids you might want to elevate your operations.