Said merely, a punch laser combines the flexibleness of a laser machine with a quick turret punch machine.

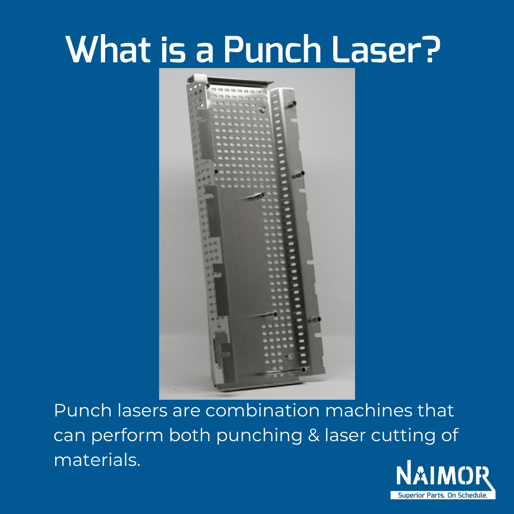

Punch lasers are mixture machines that may carry out each punching and laser reducing of sheet metallic. These machines mix the velocity of punching machines with the laser’s flexibility to chop complicated shapes.

How does a punch laser work?

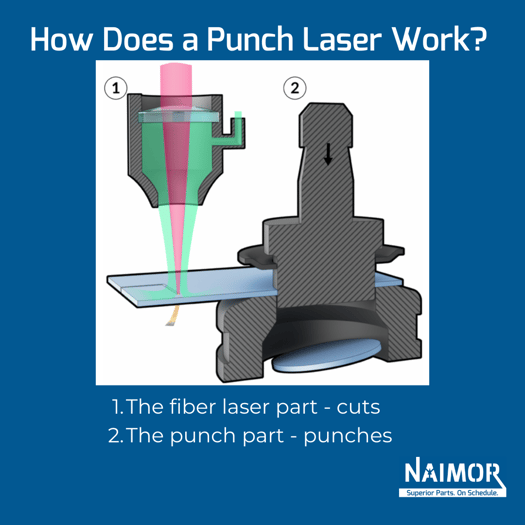

A punch laser has two predominant processes to it and makes use of a CNC interface to regulate each the punch and lasers individually. There’s the laser that has the power to chop complicated inside and outer contours with excellent edge high quality. The laser is ready to begin and cease the place wanted to permit it to extra across the sheet and lower shapes bigger and extra intricate than the punching instrument will permit. This leads to decrease tooling prices for the reason that laser has the power to chop any form the place punch tooling isn’t accessible.

And there’s the punching head that’s extraordinarily quick with punch patterns, akin to circles. This enables for small batch and excessive quantity jobs to be achieved in a short time.

The punch laser has a sheet metallic punching instrument within the form that must be lower. And makes use of thick turret tooling, which suggests it may be a single hit or a cluster instrument. A cluster instrument is a number of punches grouped collectively in a single instrument.

Punch tooling consists of two elements: a punch on the highest that’s pushed by means of the fabric by the striker. And the die which in a blanking operation the die is made with clearance to permit for the fabric being punched to clear the instrument. This punching instrument will get hammered on the highest and punches down by means of the metallic permitting the form to be lower out.

There are two types of laser reducing machines: CO2 and fiber laser.

CO2 Laser

CO2 lasers are nice for reducing thicker supplies. They ship sooner preliminary piercing occasions, faster straight line reducing and a smoother floor end when reducing supplies above 0.197” (5mm).

CO2 lasers typically produce higher edge high quality on plate stainless and aluminum elements. And so they permit higher flexibility when working with non-metal supplies.

Nonetheless, CO2 lasers use considerably extra energy and take up a bigger footprint than fiber lasers. And it requires extra gasoline and upkeep.

Fiber Laser

Fiber laser is the newer know-how in reducing and is quickly overtaking CO2 lasers within the manufacturing business. They’re comparatively upkeep free machines which have an extended service life.

Fiber laser reducing machines are additionally smaller than CO2 laser machines. These machines have elevated reducing speeds by as a lot as 25% when in comparison with machines that use CO2 lasers.

NaiMor is within the means of buying a fiber punch laser machine to exchange our CO2 punch laser machine. This can permit for elevated velocity of processing and permit for a greater variety of supplies. Along with enhancing value and effectivity.

The Advantages of a Punch Laser

These machines have all of the performance of a turret punch with the added worth of a laser. In addition they cut back the time delay related to secondary operations. Trendy punch lasers have the power to carry out operations that may usually want a second machine. Reminiscent of 90 diploma bends, tapping holes, deburring, and different operations.

A punch laser machine is beneficial when initiatives require processes that may use a number of machines. These machines can maximize flooring house, reduce work in course of, and enhance total flexibility to manufacture all kinds of elements.

These machines are additionally extremely helpful when an element requires many perforations. As a result of a laser doing many cuts subsequent to one another will deform the metallic as a result of warmth launched from the laser.

With the punch laser, NaiMor is ready to make completely spherical circles. One other advantage of the punch laser is the excessive velocity and flexibility of those machines. Due to the punch lasers‘ versatile capabilities, it permits us to course of various kinds of uncooked supplies in a lot of methods.

Why NaiMor?

At NaiMor we satisfaction ourselves on our fast response occasions and speedy manufacturing charges for all our completed elements. We additionally make use of operators who’ve a deep information base and abilities to match.

At NaiMor now we have a 33 ton punch 1.5kW laser that may deal with metallic sheets as much as 48” x 120”.

NaiMor ensures high tier work, all achieved in home. See our weblog publish for additional data on our punch laser companies!

Chrome steel elements destined for espresso machines!

Chrome steel elements destined for espresso machines!

Take a look at our instagram for a lot of extra images and movies of our work!