Fiber laser reducing stands out for its distinctive precision, velocity, and flexibility. At Ameritex, we perceive that delivering the best high quality merchandise is crucial to your success, which is why we frequently put money into state-of-the-art applied sciences like fiber laser optics. By leveraging this superior know-how, we are able to offer you superior options tailor-made to your distinctive wants. Let’s discover how fiber laser reducing works, its benefits over different laser reducing strategies, and the way it can improve your customized fabrication initiatives.

How Does Fiber Laser Chopping Work?

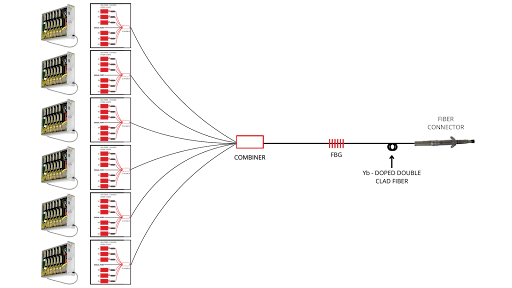

Fiber lasers are extremely concentrated beams of invisible mild that minimize by means of supplies with unimaginable precision. The method entails diodes that pump mild right into a fiber optic cable, amplifying it by means of uncommon earth components. This amplification leads to a strong, environment friendly laser beam that may simply penetrate numerous supplies.

A key innovation in fiber laser know-how is Fiber Bragg Grating, which consists of small etchings inside the fiber optic cable. These etchings manipulate mild by reflecting and refracting it, enhancing the laser’s vitality effectivity. The reducing course of is additional directed by means of a collection of lenses and mirrors within the reducing head, permitting for exact management over the reducing parameters.

One of many standout options of fiber lasers is their flexibility. Operators can simply regulate parameters corresponding to focus distance and standoff velocity, making it potential to work with numerous supplies. For instance, reducing 5083 aluminum, generally utilized in plane, will be difficult on account of its reflective nature. Nevertheless, with fiber laser know-how, we are able to obtain clear cuts with minimal effort by fine-tuning these parameters. This adaptability permits us to fulfill the distinctive wants of every buyer with precision.

5 Key Benefits of Fiber Laser Chopping

Fiber laser cutters supply a spread of advantages that assist us ship high-quality outcomes to your customized fabrication wants:

- Velocity and Effectivity: Fiber lasers are considerably sooner than CO2 lasers, particularly when reducing thinner supplies. Actually, fiber lasers will be as much as 40% sooner when working with the identical supplies. This elevated velocity interprets into shorter lead occasions and sooner mission turnarounds, serving to you meet tight deadlines with out sacrificing high quality.

- Versatility Throughout Supplies: One of many largest limitations of CO2 lasers is their problem in reducing extremely reflective supplies like aluminum and chrome steel. Fiber lasers, alternatively, can deal with a broader vary of supplies, together with reflective metals. This versatility permits us to tackle numerous initiatives, from industrial purposes to intricate designs, guaranteeing we are able to meet your particular necessities.

- Decrease Upkeep, Extra Uptime: CO2 lasers require common upkeep as a result of their focusing mirrors come into direct contact with the setting. A grimy or misaligned mirror can have an effect on minimize high quality, necessitating time-consuming recalibrations. In distinction, fiber lasers characteristic protecting window glass that shields the focusing lens, lowering upkeep wants and guaranteeing that manufacturing runs easily with minimal downtime.

- Smoother Floor Finishes: The precision of fiber lasers leads to smoother, cleaner cuts, which implies much less post-processing is required. This discount in secondary operations, corresponding to grinding or deburring, saves time and lowers total manufacturing prices. The superior floor end supplied by fiber lasers is especially helpful for initiatives requiring excessive accuracy and aesthetic high quality, corresponding to customized doorways, electrical enclosures, and switchgear panels.

- Price-Effectiveness: With sooner reducing speeds, diminished upkeep necessities, and fewer post-processing steps, fiber laser reducing know-how contributes to decrease total mission prices. This cost-effectiveness permits us to supply aggressive pricing with out compromising high quality, guaranteeing you obtain one of the best worth to your funding.

Ameritex’s Dedication to Excellence

At Ameritex, we’re devoted to leveraging the newest know-how to supply superior high quality in customized steel fabrication. Our funding in fiber laser reducing know-how permits us to boost our capabilities, streamline our processes, and meet the varied wants of our prospects.

Whether or not you’re searching for a customized door, a posh steel half, or a high-precision enclosure, our skilled staff is supplied with the information and instruments to show your imaginative and prescient into actuality. Our dedication to excellence signifies that we prioritize your satisfaction at each stage of manufacturing, guaranteeing that your mission is accomplished on time and to your precise specs.

Able to Expertise the Advantages?

If in case you have a mission that wants laser reducing, Ameritex is right here to assist. Our superior fiber laser know-how, mixed with our expert staff, allows us to ship exact, high-quality outcomes tailor-made to your wants. Contact us right now to request a quote, and let’s get began in your subsequent mission. Expertise the Ameritex distinction and see how our dedication to innovation can elevate your customized steel fabrication initiatives.