November 7, 2025 5:50 pm

At this time, agriculture and manufacturing are two of essentially the most demanding and technologically superior industries. Their progress relies upon closely on precision, effectivity, and the power to adapt rapidly to altering market calls for and environmental situations. One of the vital transformative forces behind this progress is industrial machining. With its potential to manufacture, form, and end components to precise specs, machining has turn out to be important to driving innovation and productiveness. Whether or not it’s constructing high-performance components for tractors or creating meeting line parts for factories, the function of business machining companies is pivotal.

This weblog explores the methods by which industrial machining options are revolutionizing agriculture and manufacturing. It additionally delves into the specialised function of CNC machining for agricultural purposes, the place accuracy and customization are key. As world demand for smarter, extra environment friendly equipment grows, so does the significance of precision machining in supporting that evolution.

The Position of Industrial Machining in Fashionable Agriculture

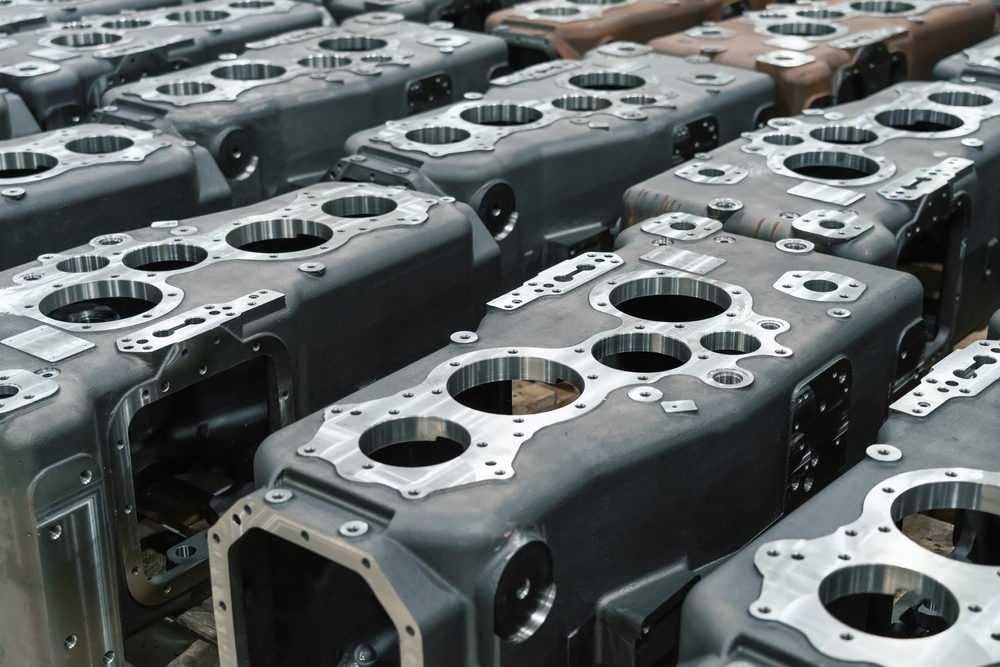

Fashionable agriculture has moved far past the period of handbook labor and rudimentary instruments. At this time, it operates on the spine of superior equipment—tractors, harvesters, irrigation programs, and precision seeders—all of which depend upon dependable parts that should face up to the check of time and excessive working situations. Right here, industrial machining companies turn out to be important by manufacturing sturdy and correct components that assist these machines.

CNC machining for agricultural tools is particularly invaluable due to its potential to provide extremely specialised parts rapidly and effectively. Farmers now depend on GPS-guided programs, automated plows, and sensible irrigation models that require precise specs to perform correctly. A minor defect in a element can compromise productiveness and result in pricey delays throughout essential planting or harvesting seasons.

Moreover, as agricultural equipment turns into extra digitized and autonomous, the demand for tight tolerances and exact geometries continues to rise. CNC machining allows producers to fulfill these rigorous necessities by utilizing computer-controlled processes to manufacture components with distinctive repeatability. From {custom} nozzles utilized in spraying programs to engine parts designed for gasoline effectivity, CNC machining for agricultural equipment performs a vital function in optimizing farm efficiency.

Advancing Manufacturing Effectivity with Machining

Manufacturing, like agriculture, is present process fast transformation. The rise of automation, robotics, and knowledge analytics has elevated expectations for precision and velocity. On the middle of those improvements are industrial machining companies that present vital assist in designing and producing machine components, instruments, and fixtures used all through manufacturing traces.

Manufacturing corporations typically function underneath tight schedules and budgets. Any failure in a manufacturing element can deliver complete operations to a halt. To mitigate such dangers, producers depend on machining companions that ship high quality parts with fast turnaround instances. CNC machining, particularly, permits for scalable manufacturing, enabling producers to check prototypes, refine designs, and transfer rapidly into full-scale manufacturing with confidence within the high quality of every half.

Industrial machining companies additionally assist sustainability efforts inside the manufacturing sector. By fabricating precision components that match collectively completely, corporations can cut back materials waste, decrease power consumption, and lengthen the lifespan of equipment. This not solely enhances environmental efficiency but additionally contributes to long-term value financial savings.

In industries corresponding to automotive, aerospace, and electronics, tolerances will be as fantastic as a thousandth of an inch. Assembly these necessities constantly could be unattainable with out superior machining capabilities. In consequence, machining suppliers should proceed investing in high-end tools, expert labor, and high quality management programs to assist the ever-evolving wants of the manufacturing {industry}.

Customization and Innovation By CNC Machining

One of the vital highly effective options of CNC machining is its potential to accommodate {custom} designs and distinctive geometries. That is particularly invaluable for each agriculture and manufacturing, the place one-size-fits-all options typically fall quick. In agriculture, for instance, soil composition, local weather, and crop sort range from area to area. Farmers might require particular attachments or configurations that aren’t out there in off-the-shelf merchandise. CNC machining for agricultural instruments permits for custom-built components tailor-made to those localized wants.

In manufacturing, the demand for innovation typically means creating new merchandise with never-before-seen options or engineering modifications. CNC machining excels at creating prototypes with fast iteration cycles, permitting engineers to check and refine their concepts quickly. These {custom} parts can then be scaled into mass manufacturing with out sacrificing high quality.

The expertise behind CNC machining can be advancing quickly. Fashionable CNC machines are able to multi-axis operations, which implies they will deal with advanced designs in a single setup. This reduces manufacturing time and will increase accuracy. Integration with CAD/CAM software program permits for seamless transition from digital design to bodily half, eliminating handbook errors and enhancing effectivity.

CNC machining’s precision and adaptableness additionally make it perfect for retrofitting or upgrading current equipment. As an alternative of changing complete programs, producers and farmers can use custom-machined parts to reinforce efficiency or lengthen the lifetime of their tools. This makes CNC machining not solely a device for innovation but additionally an economical technique for sustainability.

Supplies and Strategies That Drive Efficiency

Industrial machining isn’t just about slicing steel. It includes a broad spectrum of supplies and methods designed to fulfill the various wants of agriculture and manufacturing. From aluminum and stainless-steel to polymers and composites, machining companies should be capable to work with all kinds of substrates. Every materials presents its personal challenges when it comes to hardness, thermal conductivity, and machinability.

In agriculture, parts typically require resistance to corrosion, moisture, and heavy put on. This implies machining suppliers should select supplies and coatings that may survive in outside and abrasive environments. For instance, tillage instruments and plow blades could also be coated with wear-resistant finishes to reinforce sturdiness.

In manufacturing, thermal and structural stability might take priority. Components utilized in high-speed manufacturing traces should resist warmth deformation and preserve dimensional accuracy underneath fixed use. Precision machining ensures that these components meet strict efficiency standards whereas remaining constant from batch to batch.

Superior methods corresponding to 5-axis machining, electrical discharge machining (EDM), and laser slicing have additional expanded the probabilities for creating intricate, high-performance components. These strategies enable for advanced shapes, inner channels, and fantastic particulars that had been as soon as thought unattainable. For each agriculture and manufacturing, the provision of those methods means higher performance, reliability, and innovation in end-use merchandise.

Partnering with the Proper Machining Service Supplier

Choosing the proper supplier of business machining companies can considerably affect the success of tasks in agriculture and manufacturing. A dependable accomplice brings extra than simply machines—they bring about expertise, engineering perception, and a dedication to high quality. This relationship must be constructed on clear communication, shared targets, and a deep understanding of the industry-specific challenges.

For agricultural purposes, this implies discovering a machining accomplice who understands the seasonal nature of farming and the urgency of kit availability. Fast turnaround, half availability, and customization choices are important options of a succesful service supplier. CNC machining for agricultural instruments and programs should meet each useful and time-sensitive calls for.

In manufacturing, the appropriate accomplice will be the distinction between a profitable product launch and a pricey delay. They have to supply design assist, prototyping capabilities, and scalable manufacturing. Expertise with regulatory requirements and high quality certifications can be vital, particularly in industries with excessive security or efficiency necessities.

Belief and transparency are key to long-term partnerships. Machining suppliers must be keen to share insights, recommend enhancements, and collaborate intently with purchasers to make sure optimum outcomes. As expertise continues to evolve, partnerships that embrace innovation, adaptability, and steady enchancment will thrive on this house.

Conclusion

Industrial machining options are the invisible engine behind the seen success of agriculture and manufacturing industries. From rugged tractor parts to intricate manufacturing instruments, these companies be certain that machines carry out reliably, effectively, and exactly. With the combination of CNC machining for agricultural tools and manufacturing programs, corporations are higher outfitted to fulfill the calls for of right this moment’s market.

The worth of business machining companies extends far past fabrication. It empowers innovation, allows customization, and drives sustainability. As these industries proceed to develop and adapt to new applied sciences and world challenges, machining will stay a cornerstone of their progress. By investing in high-quality machining partnerships and embracing superior capabilities, companies in agriculture and manufacturing can safe a aggressive edge and pave the way in which for future success.

Want Metal Fabricators in Hermiston, OR?

NW Steel Fabricators, Inc. is a family-owned enterprise that has been servicing prospects in Hermiston, Oregon since 1986. Now we have greater than 100 years of expertise within the food-processing {industry} and specialize within the {custom} manufacturing of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Steel Fabricators, Inc. is an accredited member of the native Chamber of Commerce. We’re a devoted enterprise the place high quality all the time comes first. Our prospects know that they will depend on us to guarantee that their merchandise are hand-crafted to fulfill their specs. Contact us right this moment to study extra about what we are able to do for you!

Categorised in: Machining

This publish was written by admin