July 10, 2025 3:53 pm

With regards to selecting the perfect metallic chopping technique to your mission, the controversy of laser vs plasma vs waterjet is unavoidable. Every of those applied sciences has made a big mark within the manufacturing trade, providing precision and flexibility in several contexts. Whether or not you’re constructing high-precision elements, working with thick industrial plates, or creating intricate designs in delicate supplies, the correct alternative depends upon a number of key components. Let’s dive right into a complete metallic chopping strategies comparability so you can also make an knowledgeable, assured determination to your subsequent mission.

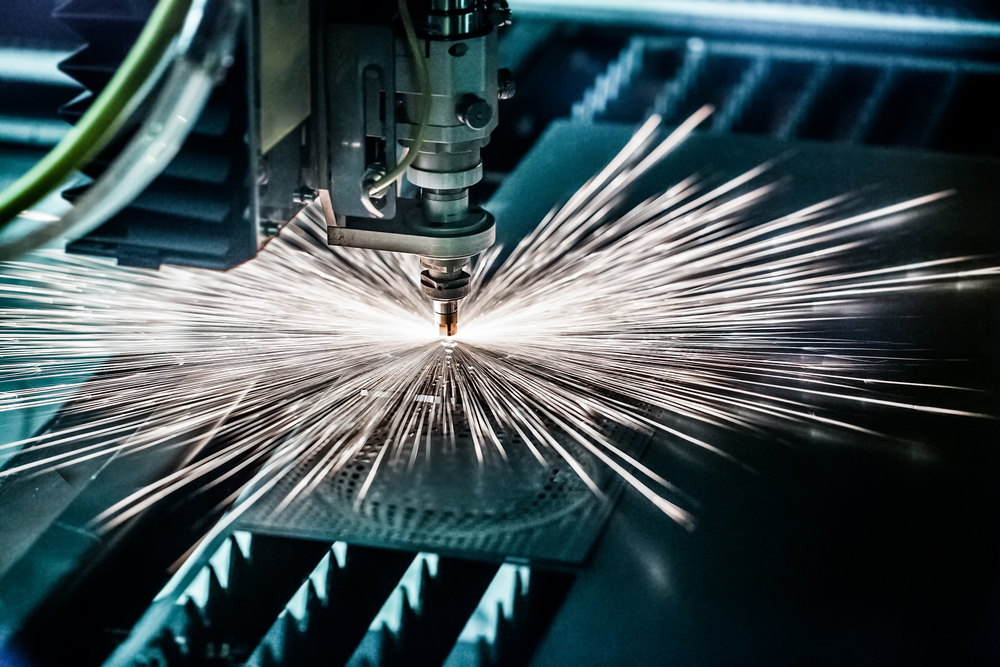

Laser Chopping

Laser chopping is a high-precision, non-contact chopping technique that depends on a centered beam of sunshine to soften, burn, or vaporize materials. It’s famend for its extraordinary accuracy, with the flexibility to realize extraordinarily superb tolerances and minimal kerf width. Laser chopping excels at chopping skinny to medium-thickness supplies, sometimes as much as about 1 inch for metal, and even increased for non-ferrous metals or plastics relying on the facility of the laser. It’s notably suited to purposes that demand excessive repeatability and sharp, clear edges with minimal ending work.

One of many key strengths of laser chopping is its velocity on skinny supplies. As a result of the beam is so concentrated, it may well transfer quickly by way of sheet metallic whereas producing crisp, detailed cuts. This makes laser chopping extremely engaging for industries akin to aerospace, electronics, medical gadgets, and automotive, the place precision and tight tolerances are essential. As well as, trendy laser cutters can combine CNC techniques to automate advanced design patterns with outstanding consistency.

Nevertheless, laser chopping does include limitations. As materials thickness will increase, laser chopping can wrestle to take care of edge high quality, with attainable tapering or heat-affected zones. Extremely reflective metals, akin to copper or brass, may pose challenges, requiring specialised tools or changes to keep away from laser beam reflection that may injury the equipment. And whereas laser cutters are versatile, their capital price might be comparatively excessive, particularly for industrial-grade techniques. Nonetheless, in case your mission prioritizes tight tolerances and excessive manufacturing velocity on skinny to reasonable supplies, laser chopping is a compelling choice.

Plasma Chopping

Plasma chopping takes a distinct strategy by utilizing a high-velocity jet of ionized fuel, or plasma, to soften and sever conductive supplies. The plasma arc reaches temperatures nicely past 20,000°C, immediately vaporizing metallic and blowing it away with a robust fuel stream. Plasma chopping has grow to be a staple within the fabrication world, appreciated for its robustness, affordability, and talent to chop thicker metals with relative ease.

By way of thickness, plasma chopping has a big benefit over laser chopping. It could deal with gentle metal as much as 2 inches thick or extra, relying on the system’s amperage. It’s also fairly quick on medium to thick supplies, making it extremely cost-effective for industrial purposes like shipbuilding, heavy tools, structural metal fabrication, and metallic recycling. If you happen to’re coping with structural metal or different heavy-gauge supplies, plasma can shortly ship the outcomes you want.

Nevertheless, there are trade-offs. Plasma chopping usually has a wider kerf and fewer exact tolerances in comparison with laser chopping, which suggests extra secondary ending work could also be required. The warmth-affected zone can also be bigger, which may trigger slight warping on skinny or delicate supplies. Whereas plasma cutters are moveable and versatile, they’re restricted to conductive supplies and can’t be used on glass, wooden, or ceramics.

When balancing price, velocity, and thickness capabilities, plasma chopping is an impressive middle-ground answer. For a lot of metalworking outlets, the plasma cutter provides a mix of affordability, ruggedness, and effectivity that’s exhausting to beat, particularly in environments the place excessive quantity or heavy-duty initiatives dominate.

Waterjet Chopping

Waterjet chopping is one other versatile technique, utilizing an ultra-high-pressure jet of water, typically combined with an abrasive, to erode and lower by way of supplies. The standout benefit of waterjet chopping is its capability to course of just about any materials: metals, composites, stone, glass, ceramics, and even rubber or foam. This common functionality makes it a favourite in industries with various materials necessities, akin to structure, aerospace, and creative fabrication.

In contrast to laser and plasma chopping, waterjet chopping is a cold-cutting course of. This implies there isn’t any heat-affected zone in any respect, preserving the mechanical properties of the fabric and eliminating issues about warping or micro-cracking attributable to thermal stress. This makes waterjets excellent for supplies vulnerable to warmth distortion or delicate composites that may degrade underneath excessive temperatures.

Waterjets can deal with extraordinarily thick supplies as nicely, as much as 12 inches or extra relying on the pump stress and abrasive sort. Additionally they provide distinctive precision, with tolerances akin to laser chopping, although sometimes at a slower chopping velocity. The flexibility comes at a value, although: waterjet techniques are inclined to have increased working prices, together with abrasive media, water recycling, and upkeep. Additionally they usually lower extra slowly than plasma or laser cutters, making them much less environment friendly for high-volume, high-speed manufacturing runs.

For initiatives involving various, heat-sensitive, or very thick supplies — or the place a sophisticated, ready-to-finish edge is essential — waterjet chopping is a strong contender. Its versatility and cold-cutting benefits are unmatched by plasma or laser techniques, even when they require extra time and better working budgets.

How one can Select for Your Mission

The laser vs plasma vs waterjet debate finally boils all the way down to understanding your mission’s priorities. First, think about materials sort. If you happen to’re solely chopping conductive metals, plasma is likely to be your greatest worth choice, particularly for thicker gauges. If you’ll want to lower a variety of supplies, together with non-conductive ones, waterjet is the clear winner.

Subsequent, take into consideration thickness. Skinny to reasonably thick supplies (underneath about 1 inch) are perfect for laser chopping, due to its velocity and superior end. For thicker metal within the 1–2 inch vary, plasma is usually less expensive and sooner. If you happen to’re going past a number of inches in thickness or want completely no thermal distortion, waterjet turns into the strongest alternative.

Precision is one other key dimension. Laser chopping provides the tightest tolerances for metals with the least secondary processing, carefully adopted by waterjet, whereas plasma is greatest for purposes the place superb tolerances are much less essential. Finances additionally performs a significant function: plasma cutters have a a lot decrease upfront price and upkeep invoice than high-power industrial laser or waterjet techniques.

Lastly, take into consideration the manufacturing atmosphere. When you’ve got high-volume wants with repeatable elements, laser chopping’s velocity and automation can dramatically increase productiveness. In a store with frequent materials modifications and one-off elements, the pliability of a waterjet could also be definitely worth the funding. And for rugged, thick, conductive metals with minimal fuss, plasma is the dependable workhorse.

Placing It All Collectively

As you weigh the professionals and cons on this metallic chopping strategies comparability, keep in mind that no single technique is universally superior. As an alternative, it’s about matching the software to the distinctive calls for of your mission. Laser chopping is the go-to for velocity and superb element on skinny supplies, providing unmatched precision and clear edges. Plasma chopping thrives in heavy metal fabrication with its cost-effective, high-speed operation on thick, conductive metals. In the meantime, waterjet shines with its cold-cutting functionality and talent to deal with just about any materials, preserving structural integrity with no heat-affected zone.

For a lot of companies, it’s price exploring hybrid options and even outsourcing sure cuts to specialised outlets with the correct tools, slightly than investing closely in all three applied sciences. Advances in CNC controls and software program imply every of those techniques might be programmed to supply advanced elements with repeatable high quality, making all of them viable relying on the circumstances.

Finally, by understanding your materials varieties, thicknesses, precision wants, manufacturing quantity, and price range, you may confidently select the correct technique. Whether or not you’re prototyping precision aerospace brackets, chopping structural beams for a skyscraper, or creating ornate stone signage, figuring out the strengths of laser, plasma, and waterjet chopping will empower you to pick the perfect know-how for flawless outcomes.

This holistic, considerate strategy ensures your subsequent mission will profit from essentially the most environment friendly, cost-effective, and high-quality chopping course of accessible — a wise funding to your group and your backside line.

Want Metal Fabricators in Hermiston, OR?

NW Steel Fabricators, Inc. is a family-owned enterprise that has been servicing prospects in Hermiston, Oregon since 1986. Now we have greater than 100 years of expertise within the food-processing trade and specialize within the customized manufacturing of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Steel Fabricators, Inc. is an accredited member of the native Chamber of Commerce. We’re a devoted enterprise the place high quality all the time comes first. Our prospects know that they’ll depend on us to be sure that their merchandise are hand-crafted to satisfy their specs. Contact us at the moment to be taught extra about what we will do for you!

Categorised in: Steel Chopping

This put up was written by admin